Small concrete pump control system casting micro hydraulic concrete pump

- $2899.00 / 1 - 1 sets

$2499.00 / 2 - 4 sets

$2199.00 / >=5 sets - 1 set

- Zhengzhou Hengyou Machinery Manufacturing Co.,Ltd.

- Henan, China

- Ms You Heng

PRODUCT DETAIL

| maximum. Horizontal conveying distance: | 40-60 | Core components: | pressure vessel, engine |

| Key words: | Conveying concrete equipment | Applicable industries: | Mechanical Repair Shop, Construction Engineering |

| weight: | 600 kg | brand: | Hengyou |

| Function: | construction | Marketing Type: | New Products 2021 |

| Video external inspection: | if | Unique Selling Points: | high load moment |

| Type of engine: | Diesel engine power | Card: | Hengyou |

| feature: | easy to use | Dimensions (L*W*H): | 1400*700*1100mm |

| maximum. Vertical conveying distance: | 20 | application: | construction project |

| Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil | port: | Qingdao, Tianjin |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Mechanical test report: | if |

| Core Components Warranty: | 1 year | capacity: | 5~8m3/h |

| After-sales service provided: | Yes | Packaging Details: | Concrete pump tube, rubber hose, electrostatic concrete delivery pump, bare packaging, concrete pump machine, FCL, plywood box packaging, LCL container. |

| Supply capacity: | 500 sets per month | Power Type: | electrical |

| Warranty: | 1 year | productivity: | 5-8M³/H |

| engine: | electric | Health status: | new |

| place of origin; place of origin: | Henan, China | Motor Power: | 15kW |

Product Description

1. The special pouring pump for secondary structure fine stone mortar can realize the transportation of fine stone concrete and mortar for long-distance high-rise buildings.

2. The distribution valve adopts advanced S-pipe valve, which has good sealing performance and simple and reliable structure.

3. Eye plate (commonly known as wear plate) and floating cutting ring are made of hard alloy, which has good wear resistance, long service life and easy replacement. The cutting ring automatically compensates for the gap structure.

4. The machine adopts electro-hydraulic control mode, with perfect electro-hydraulic overload capacity

Protection and instrument display system. With anti-pump running function, it is easy to eliminate blockage faults. The pumping speed can be adjusted to meet various working conditions.

Protection and instrument display system. With anti-pump running function, it is easy to eliminate blockage faults. The pumping speed can be adjusted to meet various working conditions.

5. The centralized lubrication system is automatically controlled by the program to start, stop and run, which effectively prolongs the service life of the rotating parts.

6. Electrical components such as contactors and button switches work reliably, the control circuit is simple, and switches are installed in the electrical box, which is easy to operate.

7. The main seal adopts high-quality seals to prevent internal and external leakage of the hydraulic system.

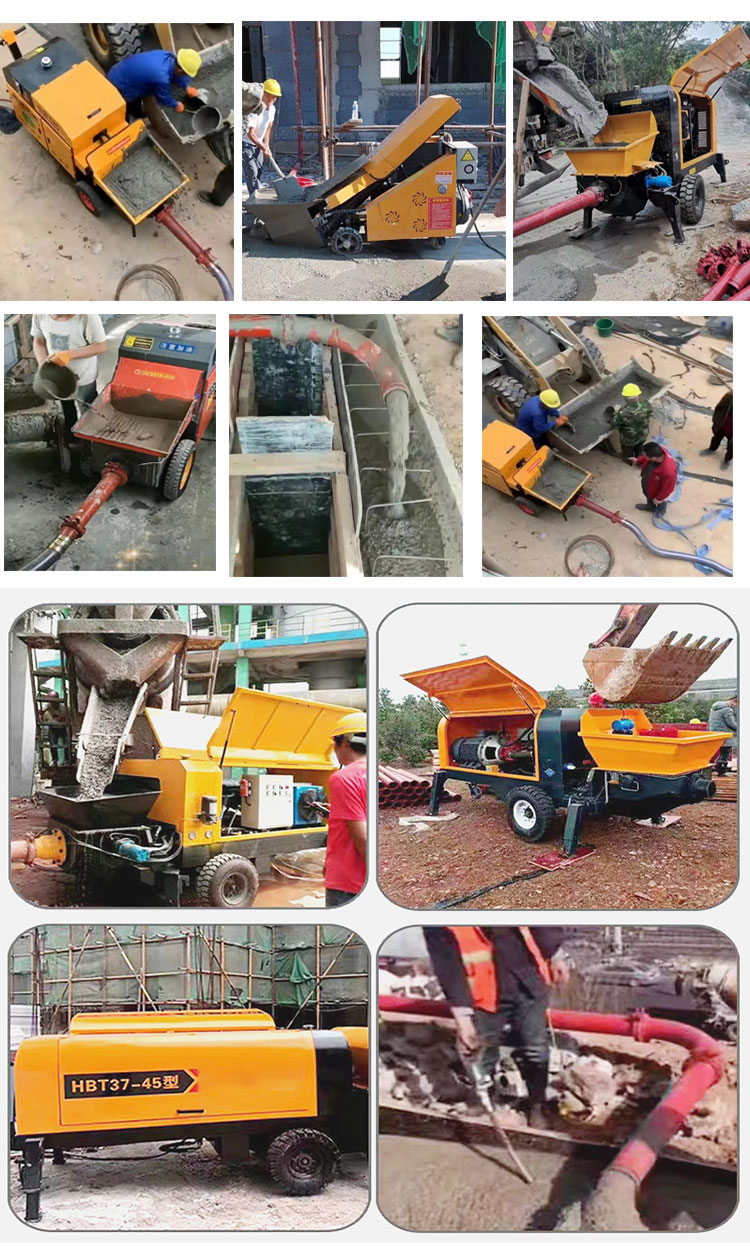

Construction Site

Product parameters

detailed picture

Electronic control system

Wired remote control device for easy remote operation. The electrical control system adopts famous brand electronic components.

cooling system

The radiator equipment makes the working oil temperature of the hydraulic system lower than 70 ℃, so that the machine is in a normal state.

computer system

To ensure good pumping and reduce sticking, the glasses wear plate and cutting ring are made of high wear-resistant carbide material. This concrete pump can work with lower wear and longer life of components. Glasses wear plates can be replaced up to 30000cbm.

Double open hydraulic circuit

Equipped with two pumps, it makes the whole hydraulic system simpler. The reliability of the entire system is also greatly improved, and the service life of the components is greatly extended. This facilitates judgment and troubleshooting.

workshop

The company's six core advantages

1. Exported to more than 70 countries and regions

2. Lifetime free after-sales service

3. Direct manufacturing

4. Customize

5. Thickened plate

6. Live show machine

7.prompt goods, 1-2 days delivery

Our market has covered all regions of China, and has been exported to more than 90 countries and regions such as Europe, the United States, Australia, Japan, and the United States. With rich experience in import and export, we can provide diversified machinery and equipment for international friends from all over the world.

2. Lifetime free after-sales service

3. Direct manufacturing

4. Customize

5. Thickened plate

6. Live show machine

7.prompt goods, 1-2 days delivery

Our market has covered all regions of China, and has been exported to more than 90 countries and regions such as Europe, the United States, Australia, Japan, and the United States. With rich experience in import and export, we can provide diversified machinery and equipment for international friends from all over the world.

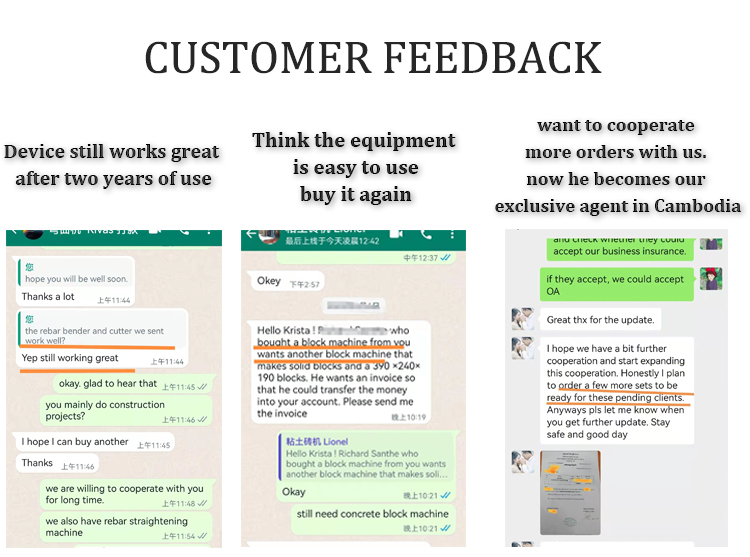

customer feedback

VIEW MORE

YOU MAY LIKE

Other Products

-

Custom Mini Concrete Pump Diesel Small Portable Concrete Delivery Pump Concrete Pump Price$2199.00 - $2899.00 / set

Custom Mini Concrete Pump Diesel Small Portable Concrete Delivery Pump Concrete Pump Price$2199.00 - $2899.00 / set -

1m3 2m3 2.5m3 3m3 4m3 5m3 6m3 concrete mixer truck price Howo concrete mixer truck$2199.00 - $11998.00 / set

1m3 2m3 2.5m3 3m3 4m3 5m3 6m3 concrete mixer truck price Howo concrete mixer truck$2199.00 - $11998.00 / set