Small volume plastic to gasoline engine pyrolysis plant with ISO/CE

- $15000.00 /set

- 1 set

- Henan Barui Environmental Protection Equipment Co., Ltd.

- Henan, China

- Mr Andy Lee

PRODUCT DETAIL

| commodity: | Small-capacity plastic gasoline engine cracker | year: | new |

| Applicable industries: | Manufacturing, Energy & Mining | Weight (kg): | 13000kg |

| Mechanical test report: | if | delivery time: | 30 working days |

| After-sales service provided: | Engineers can service machinery overseas, on-site installation, commissioning and training | cooling method: | Shell and Tube Condenser |

| Workers need: | 3 per class | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Main selling point: | competitive price | Power (kW): | 16kW |

| Video external inspection: | if | Health status: | new |

| Supply capacity: | 12 pyrolysis machines per season | Tyre machine type: | tire recycling machine |

| Marketing Type: | Hot Products of 2019 | Voltage: | 380V |

| Certification: | ISO CE | Local service location: | not any |

| payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram | raw material: | MSW, plastic, rubber, tires... |

| Packaging Preview: | port: | Qingdao, Lianyungang, etc. | |

| Dimensions (L*W*H): | 2250mm*11500mm | heating method: | Coal, fuel oil, natural gas or other |

| Warranty: | 1 year | Service life: | 5 years |

| Core Components Warranty: | 3 years | Installation type: | Mounted; Skid Mounted; Truck Mounted |

| Core components: | pressure vessel | type: | tire machine |

| Packaging Details: | All items are packed in export standard to ensure no damage in transit. | place of origin; place of origin: | Henan, China |

| brand: | Barry | Showroom location: | not any |

| Type of machine: | batch processing |

Title: Small Volume Plastic to Gasoline Cracker with ISO/CE

Product Description

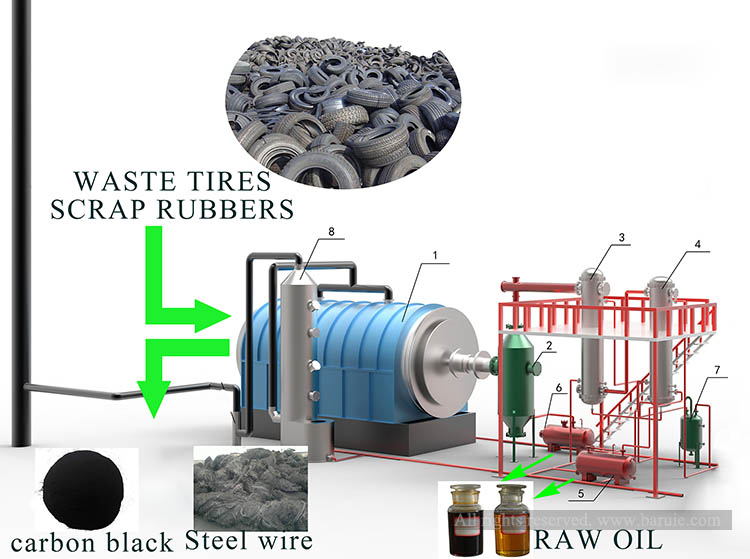

1T 2T 3T Turck loading skid equipment plastic pyrolysis machine for sale

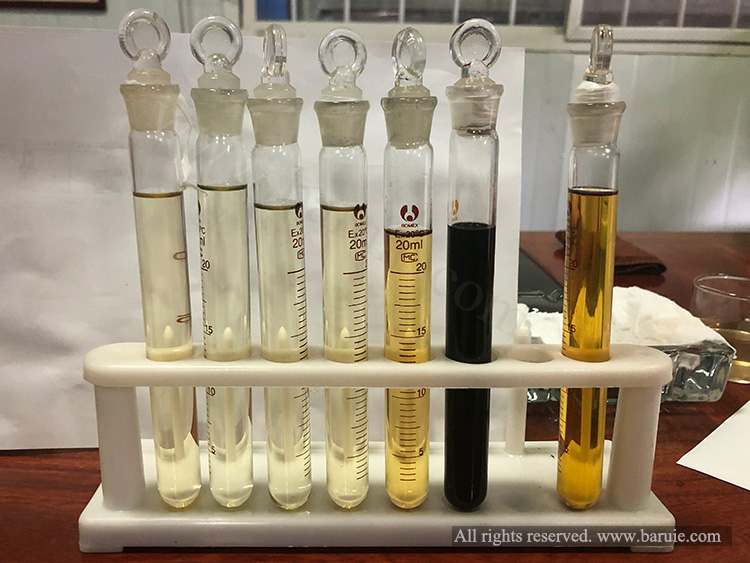

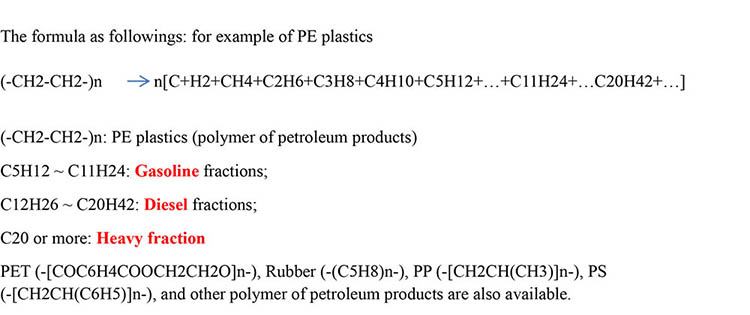

Oil made from waste plastic and tires

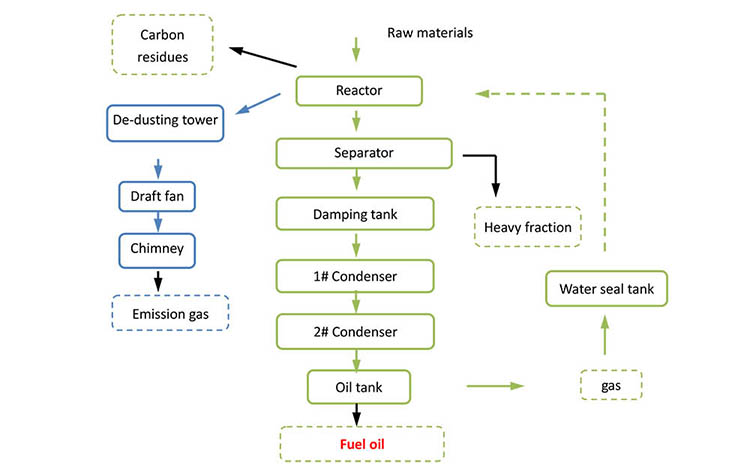

| 1. Process flow of cracking equipment |

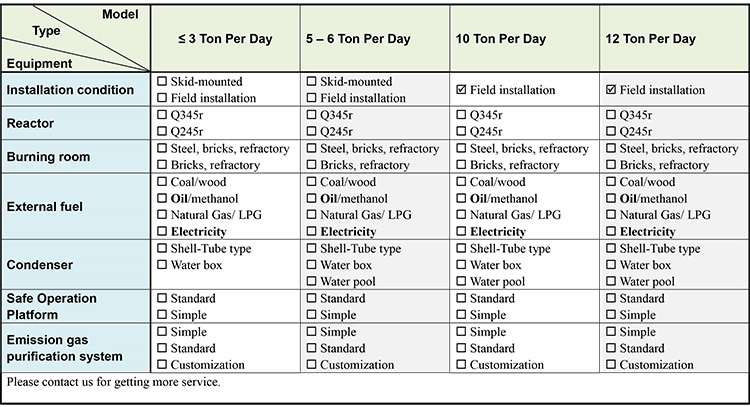

| 2. Type of cracking equipment |

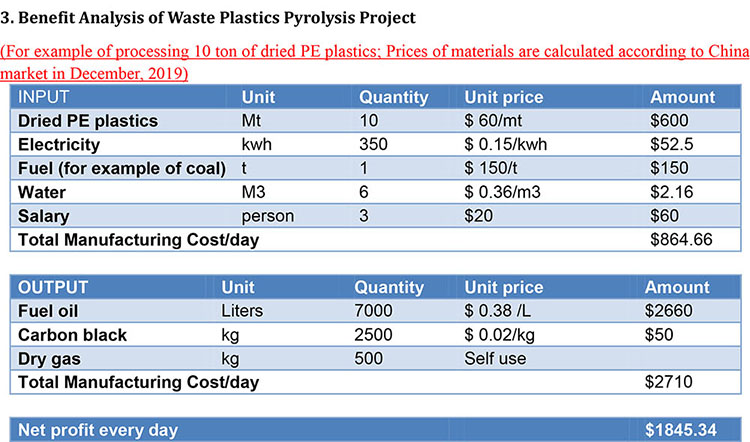

| 3. Benefit analysis of cracking equipment |

| 4. Manufacturing of plastic recycling equipment |

| Do not. | equipment | Purpose |

| 1 | Pyrolysis reactor | Pyrolysis/pyrolysis under anaerobic conditions; converts plastics to oil vapor |

| 2 | Multistage Separator | Separation of heavy residues from light components |

| 3 | Condensers and Water Coolers | After cooling, the gas phase oil turns into a liquid. |

| 4 | water seal | The exhaust gas can be washed with water to prevent the exhaust gas from flowing backwards. |

| 5 | Dust removal tower | Remove dust and odors from exhaust gas |

| 6 | unloader | Automatic discharge of carbon black |

| 7 | Oil vapor separator | Separation of gas from naphtha |

Packaging and Shipping

VIEW MORE

YOU MAY LIKE

Other Products

-

China Made Heavy Fuel Oil Distillation Mini Refinery$50000.00 / set

China Made Heavy Fuel Oil Distillation Mini Refinery$50000.00 / set -

Sell 100-1000 TPD Crude Oil Refining Equipment Machine$100000.00 / set

Sell 100-1000 TPD Crude Oil Refining Equipment Machine$100000.00 / set -

Small Crude Oil Refinery Distillation Unit Price$300000.00 / set

Small Crude Oil Refinery Distillation Unit Price$300000.00 / set