tire recycling production line rubber tire recycling

- $50001.00 /set

- 1 set

- Changzhou Optima Technology Co., Ltd.

- Jiangsu, China

- Mr Richard Xu

PRODUCT DETAIL

| Type of tire machine: | tire recycling machine | train: | supply |

| Warranty: | 1 year | Type of machine: | Granulator, Garbage Shredder, Grinder, Shredder |

| brand: | Optima | After warranty service: | Video technical support, no service, spare parts, on-site maintenance and repair services |

| Core component warranty: | 1 year | port: | Shanghai, Ningbo |

| Tire size: | 1200mm | Packaging Details: | PE film or carton. |

| Key words: | tire separator, tire shredder, tire recycling | Applicable industries: | Energy and Mining |

| Function: | Rubber production line, cutting tires, shredding tires, grinding powder | Core components: | PLC, bearings, motors, gears |

| place of origin; place of origin: | Jiangsu, China | Showroom location: | United States, Kazakhstan |

| Marketing Type: | New Products 2020 | Main selling points: | automatic |

| payment terms: | L/C, D/P, D/P, T/T | Name: | recycling tire machine |

| capacity: | 500kg/h to 10t/h | Mechanical test report: | if |

| Install: | supply | After-sales service provided: | Video Technical Support |

| Tire Type: | Truck Tires, Passenger Tires, SUV Tires, Bus Tires | Power (kW): | 328 kW |

| Voltage: | 380v | Local service location: | Kazakhstan |

| Health status: | new | Video shipment inspection: | if |

| type: | tire machine | Weight (kg): | 100000 kg |

| Supply capacity: | 10 sets per quarter | Finished goods: | TDF/TDA/rubber covering/rubber crumb/rubber powder, steel, fiber |

Product Description

Waste tire shredder truck tire car tire Dura shredding rubber powder machine recycling production line

Optima uses its experience and success to continuously improve the design and manufacture of our tire recycling systems, making them more effective and efficient throughout the recycling process.

Name | TDF/TDA Rubber Shredder Shredding Machinery Waste Tire Machine Tire Recycling Plant |

tire type | Car Tires, Truck Tires, SUV Tires |

maximum. size | 1200mm |

Completed | TDF/TDA, rubber covering, rubber crumb, rubber powder |

capacity | 500kg/hr, 1000kg/hr, 1500kg/hr, 3000kg/hr, 5000kg/hr |

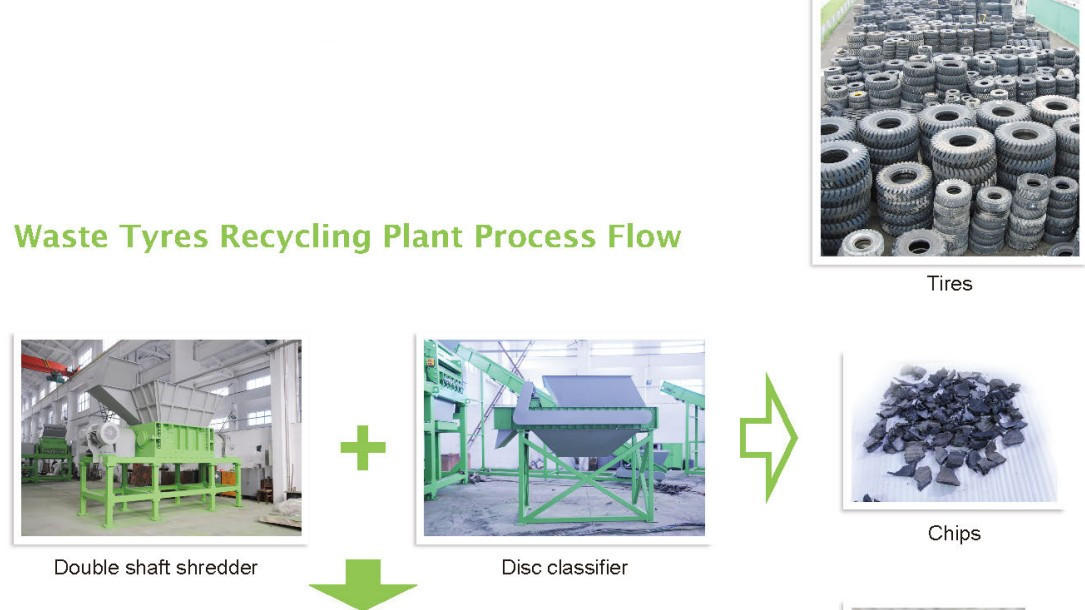

Tire Shredder Instructions

1. Double shaft shredder

Optima's twin-shaft shredders are designed with aggressive low-speed, high-torque shredding technology. Each axle is driven by its own Siemens motor, giving it plenty of power to drive the tires and thick steel balls. Shredder blades range in thickness from 25mm to 152mm (1''-6") depending on tire type, throughput and desired end product. Shredders can process up to 10 tons per hour OTR tires, truck tires and car tires.

2. Grater

Graters are the ultimate machines for mid-stream grinding and steel separation. It is specifically designed to process pre-shredded tire shreds and produce wire-free rubber coverings between 25-12 mm (1" - 0.5"). The grater can process up to 6 tons of raw material per hour. The main rotor housing is equipped with replaceable wear plates to increase the durability and life of the cutting chamber. Another unique feature of this machine is the ability to turn the knives once before they have to be sent for sharpening or replacement, minimizing operating costs.

3. Granulator

The granulator is designed to grind the rubber mulch in the grater into small particles down to 1 mm. Particles are screened and recycled until they reach the desired size. Due to the design of the pelletizer and the precise alignment of the blades, the pelletizer produces a very uniform cut and high quality pellets. During the pelletizing process, 99% of the fibers are removed, leaving uncontaminated rubber pellets ready for further processing or sale.

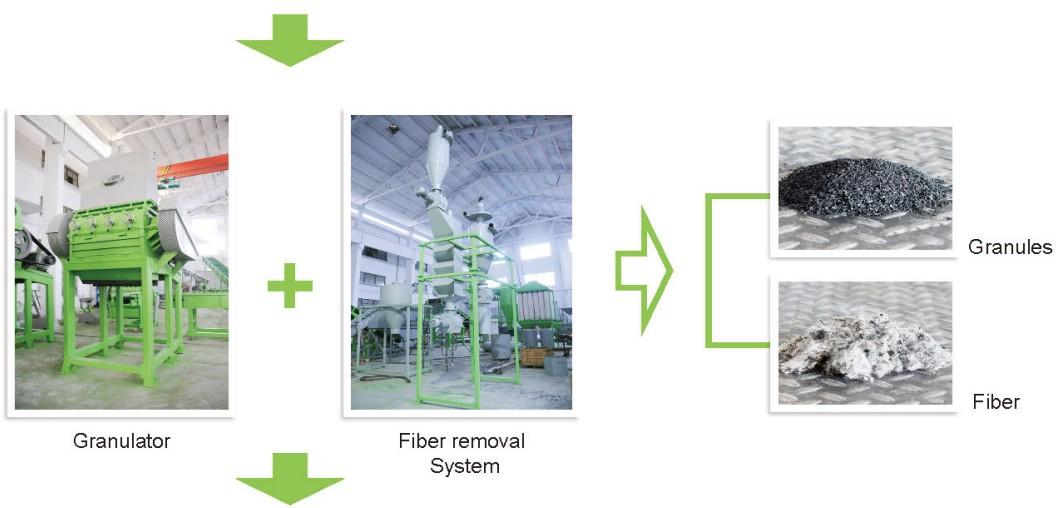

Description of Tire Shredding Plant

The tire shredder is used to recycle waste tires of different models such as cars, light commercial vehicles, SUVs and trucks, from shredding, crushing, wire and fiber separation to produce pure rubber granules and powder. Intelligent design, PLC control, production capacity range 500kg/hr-3000kg/hr, equipment or workshop can be customized according to customer needs.

detailed image

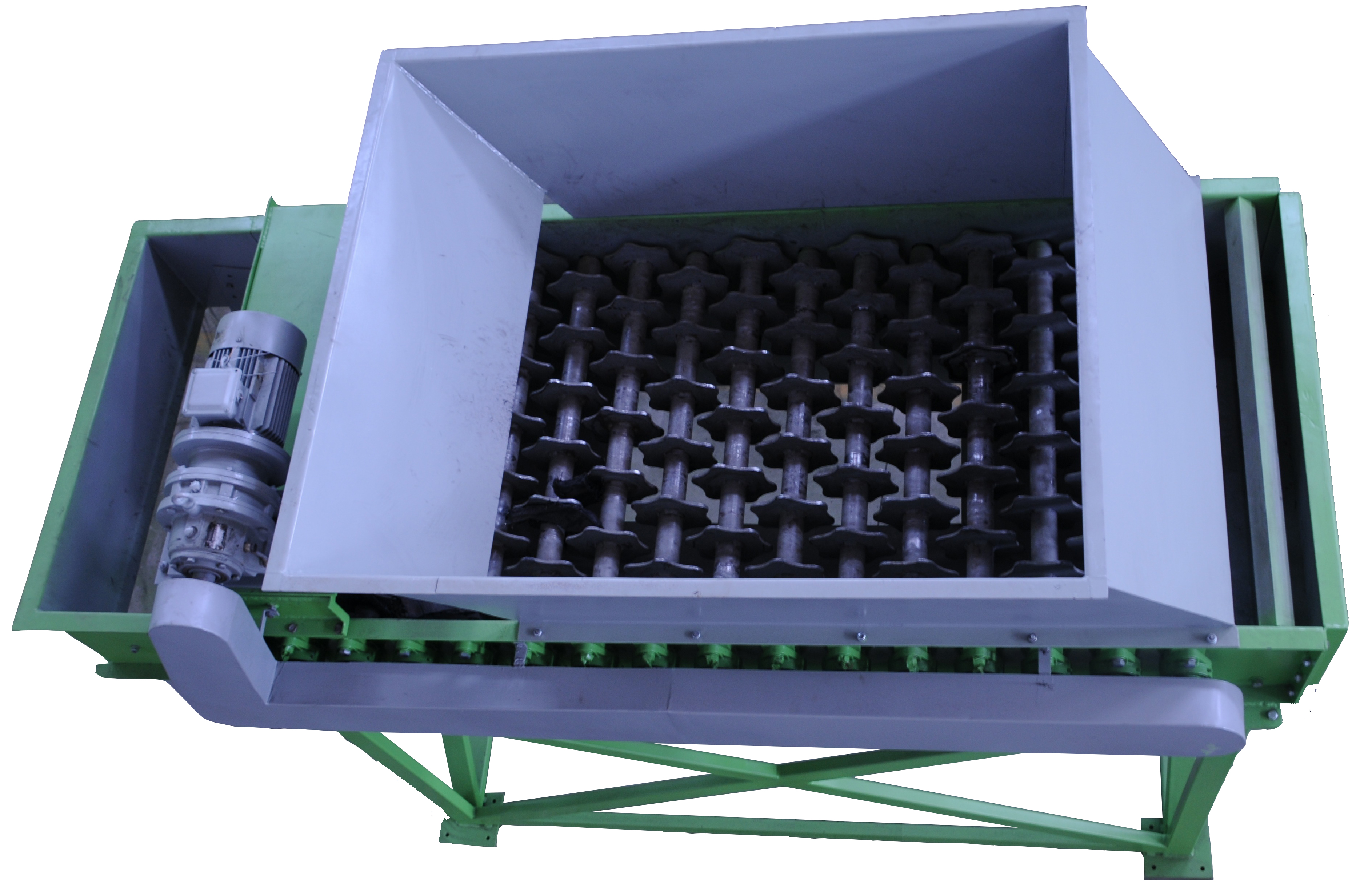

Dual Shaft Shredder Blades and Spacers.

Disc separator.

Rubber grinder.

VIEW MORE

YOU MAY LIKE