The cheapest granulator German screen changer granulator production line has discounts on plastic granules

- $3450.00 /set

- 1 set

- Jiangsu Turui Machinery Co., Ltd.

- Jiangsu, China

- Ms Tina Wan

PRODUCT DETAIL

| Core component warranty: | 1 year | Warranty: | 1 year |

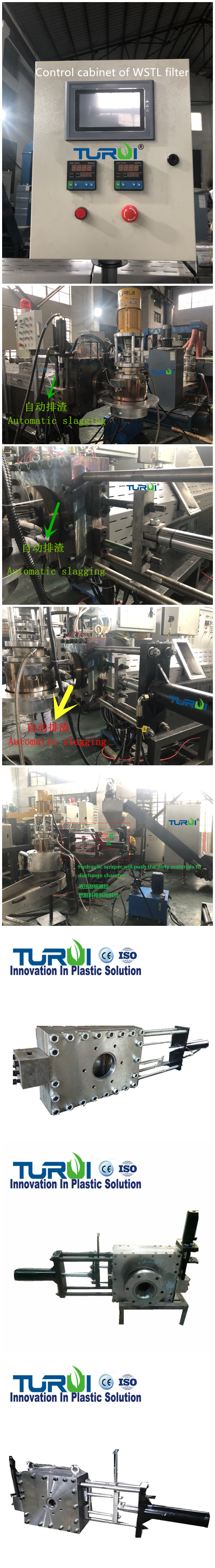

| Name: | Plastic granulator laser panel filter | Control System: | electric box |

| application: | filter plastic | Origin: | Jiangsu, China |

| Net hole size: | 20 mesh, 30 mesh, 40 mesh, 60 mesh, 80 mesh | Weight (kg): | 500 |

| Video outbound inspection: | if | Certificate: | CE |

| Marketing Type: | 2020 New Products | Showroom location: | Russia |

| Main selling points: | easy to operate | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| Mechanical test report: | if | Input voltage: | 380V 50hz or as required |

| Core components: | Parts | For plastics: | PP PE ABS PC PA |

| Material: | alloy | Health status: | new |

| brand: | Turui | Raw material network: | Hardness 60 degrees |

| Applicable industries: | Manufacturing plant, plastic processing | Supply capacity: | 5 sets per month |

Product Description

Structural specifications:

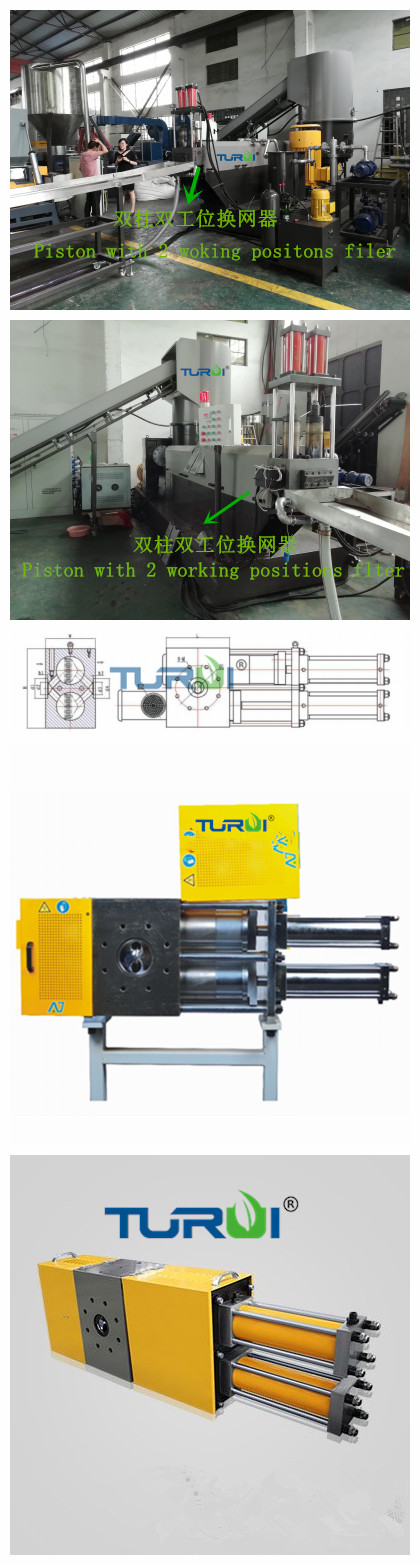

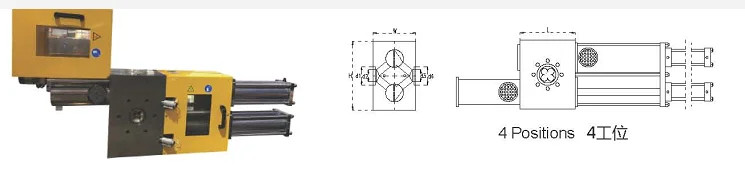

Double-cylinder, double-channel double-network or double-channel four-network structure, using lengthened variable exhaust mechanism. When changing the screen, the two runners work one by one, feeding continuously

Applications:

Plate, sheet, high-end pipe industry, high-end granulation (modification), various sols, adhesives, etc.

Features:

1. Double flow channels and double stations work at the same time, with high output and large filtration capacity. The advantages of rotary screen and curved screen are complementary.

2. The perforated plate, the backwash bracket and the flow channel cooperate with each other, so that the screen changer can ensure the continuous production of the product no matter it is in the state of backwashing or changing the screen.

3. Double-station structure, no idle filter, reject cold material. There is no need to clean the remaining material and perforated plate when replacing the screen

Double-cylinder, double-channel double-network or double-channel four-network structure, using lengthened variable exhaust mechanism. When changing the screen, the two runners work one by one, feeding continuously

Applications:

Plate, sheet, high-end pipe industry, high-end granulation (modification), various sols, adhesives, etc.

Features:

1. Double flow channels and double stations work at the same time, with high output and large filtration capacity. The advantages of rotary screen and curved screen are complementary.

2. The perforated plate, the backwash bracket and the flow channel cooperate with each other, so that the screen changer can ensure the continuous production of the product no matter it is in the state of backwashing or changing the screen.

3. Double-station structure, no idle filter, reject cold material. There is no need to clean the remaining material and perforated plate when replacing the screen

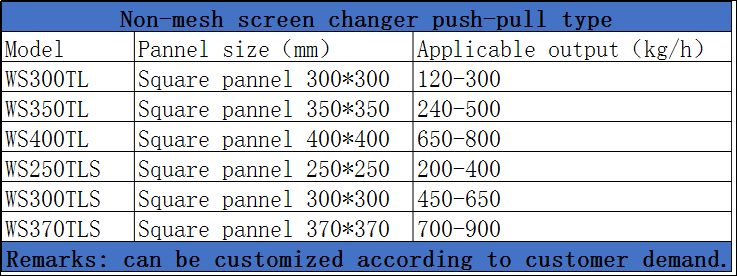

type |

Screen diameter (mm) |

Melt pressure (MPa) |

output (kg/hour) |

heating power (kilowatt) |

weight (Kilogram) |

|---|---|---|---|---|---|

| ZM50SZ-2 | Φ53*2 | ≤50 | ≤250 | 4 | 220 |

| ZM65SZ-2 | Φ68*2 | ≤50 | ≤350 | 5 | 260 |

| ZM75SZ-2 | Φ78*2 | ≤50 | ≤390 | 6.5 | 350 |

| ZM90SZ-2 | Φ93*2 | ≤50 | ≤500 | 8 | 390 |

| ZM100SZ-2 | Φ103* | ≤50 | ≤600 | 9 | 410 |

| ZM120SZ-2 | Φ123*2 | ≤50 | ≤750 | 10 | 450 |

| ZM135SZ-2 | Φ138*2 | ≤50 | ≤850 | 10.5 | 500 |

| ZM150SZ-2 | Φ153*2 | ≤50 | ≤1200 | 12 | 600 |

| ZM165SZ-2 | Φ168*2 | ≤50 | ≤1500 | 13.8 | 700 |

| ZM180SZ-2 | Φ183*2 | ≤50 | ≤2000 | 15 | 850 |

| ZM200SZ-2 | Φ203*2 | ≤50 | ≤2800 | 18 | 1080 |

| ZM255SZ-2 | Φ260*2 | ≤40 | ≤4000 | 20 | 1400 |

| ZM300SZ-2 | Φ305*2 | ≤40 | ≤5500 | number 22 | 1600 |

about Us

VIEW MORE

YOU MAY LIKE