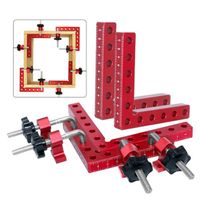

Welding Table clamping pin Welding Table clamping pin

- $5.00 /piece

- 1 piece

- Hebei Bocheng Co-Creation Measuring Tool Manufacturing Co., Ltd.

- Hebei, China

- Ms Aimee Xu

| port: | Tianjin | product name: | 3D welding station |

| MOQ: | 1 item | diameter: | 16 mm 28 mm 22 mm |

| Customization support: | OEM production | Package preview: | |

| Packaging Details: | Wooden packing | payment terms: | L/C, T/T, Western Union, MoneyGram |

| process: | CNC machining | Supply capacity: | 20000 pieces per month |

| place of origin; place of origin: | Hebei china |

Welding Table clamping pin for 3D welding table

1. 24 hours online. Whatsapp (WeChat) 008613931798614

2. Welcome to visit us to know more about our factory.

3. OEM/ODM available:

Your logo on the product.

Customize products according to your drawings.

Any ideas you have about the product, we can help you design and provide drawings.

4. After-sales service.

All products will undergo strict quality inspection in the studio before packing.

We can take over installation or clamping activities or installation planning.

We provide completed project reports. Including contracts, drawings, quotations, proforma

Invoices, technical descriptions, manufacturing schedule control plans, tests and inspections

Report, Bill of Lading, Insurance, Commercial Invoice, Packing List, Certificate of Origin.

5. Trading conditions:

MOQ: 1PC

Payment term: T/T, L/C, Paypal, etc.

Lead Time: Products in stock - 7 days. Customized products - 15-30 days

Factory produces high precision 3D welding table heavy duty

3D Welding Workbench: Five working surfaces where positioning parts can be installed. It can also be extended by any of its five work surfaces.

• Divided by material: steel welding station and cast iron welding station

• Divided according to the hole diameter: D28 series, D22 series and D16 series.

Diagonal grid: D28 is 100*100mm; D16 is 50*50mm.

Support: legs, steel frame upon request.

Components you can equip when you choose:

1. Support tools: U-shaped cube box, L-shaped cube box, angle support, angle gauge

2. Locating spare parts:

3. Clamping and fixing tools

4. Lock the workpiece spare parts

5. Auxiliary tools

feature:

• During assembly or welding, almost all workpieces can be held precisely at certain points or surfaces by means of locators, adapters, fasteners and supports.

• Inaccurate workpiece dimensions can be adjusted during pre-machining.

• It is easy to use the parts already in the workshop and simulate the assembly of the workpiece through CAD.

economy:

• Significant cost savings instead of maintaining a large number of complex and expensive traditional fixtures

• Can be used in various working conditions without any modification

• Simple and safe operation.

flexible:

• Strong enough to withstand extremely heavy loads.

• Five sides, regular holes, grid lines (no inclined holes, T-slots)

• Any workpiece can be fixed and clamped on the workbench by positioning pins

• The 3D Soldering Station can be attached to any of its five surfaces.

precise:

• During assembly or welding, virtually any workpiece can be precisely fixed at certain points or surfaces with locators, adapters, fasteners and supports

• Imprecise workpiece dimensions can be adjusted during pre-machining.

Repeatable:

• It is easy to use the parts already in the workshop and simulate the assembly of the workpiece through CAD.

Widely used in the manufacturing and processing of machinery, machining equipment, railway tracks, automobiles, motorcycles, ships, pressure vessels, sheet metal, cabinets, testing instruments, steel structures, etc.