mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

- $15000.00 /set

- 1 set

- Nuclear Industry Yantai Toncin Group Co., Ltd.

- Shandong, China

- Mr Toncin G

| port: | Qingdao or as your request | Warranty: | 1 year |

| Packaging Details: | Export or seaworthy packing or as your request | Mechanical test report: | if |

| brand: | Thongchen | Dimensions (L*W*H): | custom made |

| Applicable industries: | Energy and Mining | payment terms: | L/C, T/T |

| Install: | Technical support | Core component warranty: | 3 years |

| Marketing Type: | normal product | application: | solid-liquid separation |

| type: | mining thickener | Origin: | Shandong China |

| Company Name: | Nuclear Industry Yantai Tongxin Group Co., Ltd. | Supply capacity: | 200 sets per year |

| Material: | Carbon steel, SS 316/304 | Processing: | Yes |

| Name: | GNZ Central Drive High Speed Thickener | Video shipment inspection: | if |

| delivery time: | 2 months | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Motor type: | AC motor | brand: | Thongchen |

| Health status: | new | Showroom location: | not any |

| color: | client needs | Package preview: | |

| Weight (kg): | 20000 | Production capacity: | custom made |

| Life: | 30 years |

Mine iron ore/tailings dehydration high-efficiency thickener, sludge thickening tank, sedimentation tank

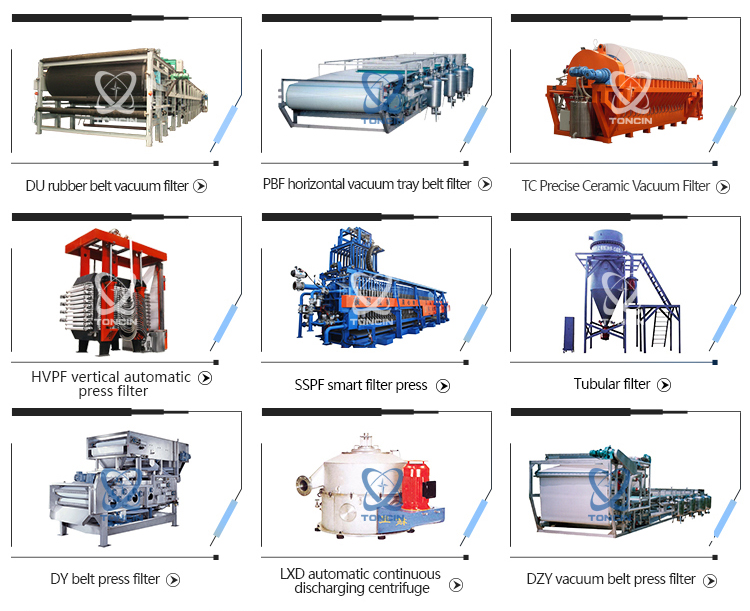

Our company takes the enrichment technology of British sunny company as the main body, and introduces and digests foreign advanced thickener technology on the basis of conventional general-purpose thickeners. The new high-efficiency thickener introduces the function of flocculant-assisted dehydration. At the same time, according to the application requirements of different industries, by optimizing the equipment structure and flocculant-assisted dehydration, the newly developed new thickener has the following advantages: the concentration efficiency is greatly improved, and the throughput is expanded. High bottom flow concentration; It has been widely used in the dehydration of various metal and non-metal ores, and the solid-liquid separation of pulp.

|

Model |

Concentrator |

Sediment area |

Lifting height of rake (mm) |

Rake speed(r/min) |

Motor Power |

|

|

Diameter (m) |

Depth (m) |

|||||

|

GNZ-3 |

3 |

2.5 |

10 |

300 |

0.1-0.2 |

3+1.1 |

|

GNZ-6 |

6 |

3.0 |

28 |

300 |

0.1-0.2 |

4+1.5 |

|

GNZ-9 |

9 |

3.2 |

63 |

300 |

0.1-0.2 |

4+1.5 |

|

GNZ-12 |

12 |

3.5 |

110 |

300 |

0.1-0.2 |

4+1.5 |

|

GNZ-18 |

18 |

4.4 |

254 |

600 |

0.1-0.2 |

7.5+2.2 |

|

GNZ-20 |

20 |

4.4 |

310 |

600 |

0.1-0.2 |

7.5+2.2 |

|

GNZ-24 |

twenty four |

5.2 |

452 |

600 |

0.05-0.2 |

7.5+2.2 |

|

GNZ-30 |

30 |

5.2 |

707 |

600 |

0.05-0.2 |

11+3 |

|

GNZ-38 |

38 |

5.5 |

1134 |

600 |

0.05-0.2 |

15+4 |

|

GNZ-45 |

45 |

5.5 |

1590 |

600 |

0.05-0.1 |

37+4 |

|

GNZ-53 |

53 |

6.0 |

2206 |

600 |

0.05-0.1 |

37+4 |

|

GNZ-60 |

60 |

6.0 |

2826 |

600 |

0.03-0.1 |

45+5.5 |

|

GNZ-70 |

70 |

6.8 |

3846 |

600 |

0.02-0.05 |

45+5.5 |

|

GNZ-85 |

85 |

7.8 |

5671 |

600 |

0.02-0.05 |

45+5.5 |

notes:

1. The above parameters are for reference only. Due to the large material settling performance, the specific parameters are subject to the design drawings provided by our company.

2. Our company can design different types of concentrators according to user requirements.

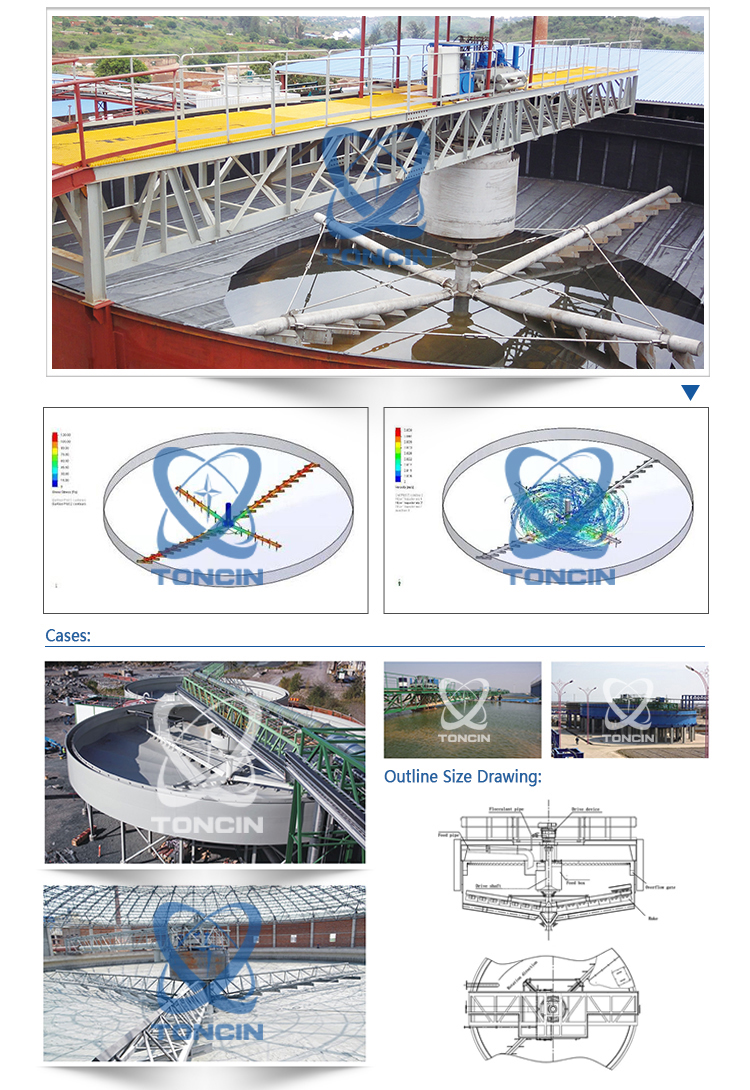

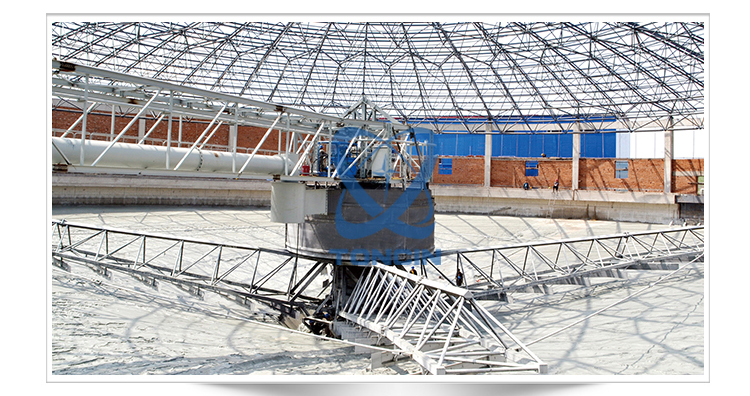

The thickener is composed of a circular thickener and a rake scraper. The solid particles suspended in the thickener settle by gravity, and the upper layer of slurry turns into clean water to realize separation. The sediment at the bottom of the thickener is continuously scraped by rakes to remove the discharged mud, and it overflows cleanly from above.

1. The efficiency of thickening and scraping is high, which is three to five times that of ordinary thickeners.

2. Excellent feeding system - high-speed feeding well:

a. The feed well degasses the feed and dissipates energy, and feeds tangentially.

b. Reasonably add flocculant to improve efficiency.

c. Equipped with a distribution plate, which can make reasonable use of the effective area of the tank.

3. The driving and lifting system with overweight design and high torque design ensures the normal operation of the equipment. The thickener will not stop under extreme conditions, increasing the efficiency of the equipment.

4. The logarithmic spiral tooth design is adopted, and the tooth density can be designed according to the material performance to improve the scraping efficiency.

5. With advanced thickener control system, automatic lifting rake, flocculant feeding, automatic control of underflow discharge pump

1. Design of main drive and rake lifting device

1) The drive frame and chassis are manufactured as heavy duty transmissions,

The operation is stable and reliable.

2) Fully automatic rake lifting.

3) Star drive, the maximum running torque is 5000,000Nm. Drive Design Torque

The transport is designed according to the following criteria.

a. Operating torque value: 33% of the design torque.

b. High torque alarm: 50% of the design torque.

c. Rake up; 60% of design torque.

d. Decreasing rake angle: 40% of the design moment.

e. Mechanical device design torque value: 150% of the design torque.

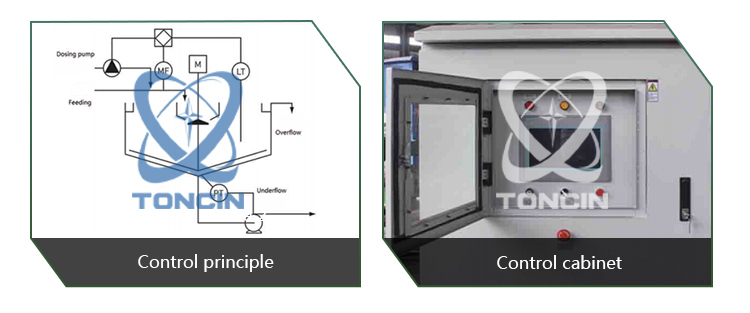

2 control system

On-site control and remote control are combined to provide DCS control points.

1. PLC control, overload protection.

2. The discharge end is equipped with a mud layer pressure sensor to control the rotation

And the pump discharges the mud.

GNZ concentrator is a new central transmission, automatic lifting rake type high-efficiency concentrator developed by our company with the introduction of foreign technology. It is widely used in coal, metal mineral processing water, metallurgy, chemical industry, tailings treatment, environmental protection, etc.

export package: We use standard export packing or as your request.

shipping: We will send our products within 2 months.

mode of transport: By sea or by air.