BTMA Large Capacity High Alumina Ceramic Ball Mill/Gold Mining Ball Mill Price/Fine Grinding Ball Mill

- $17709.00 /set

- 1 set

- Henan Benteng Machinery Co., Ltd.

- Henan, China

- Mr tom ma

PRODUCT DETAIL

| Packaging Detail: | export standard; | Condition: | New; |

| Grinding type: | Ball Frinding; | Port: | qingdao; |

| Video outgoing-inspection: | Provided; | Motor Type: | AC Motor; |

| Showroom Location: | None; | Place of Origin: | Henan; |

| Color: | Customized; | Grinding mill Finished size: | 35-325 Mesh (0.613-0.033 Mm); |

| Weight: | 8500; | Local Service Location: | None; |

| Machinery Test Report: | Not Available; | Marketing Type: | New Product 2020; |

| Market: | Africa Peru; | Core Components: | Engine,Bearing,Gear; |

| Payment Terms: | Western Union,T/T; | Supply Ability: | 15 Set/Sets per Week; |

| Warranty: | 1 Year; | Application: | grinding; |

| Warranty of core components: | 1 Year; | After-sales Service Provided: | Video technical support,Online support; |

| Applicable Industries: | Energy & Mining; | Type: | Ball Mill; |

| Brand Name: | Benteng; |

BTMA Large Capacity High Alumina Ceramic Ball Mill/Gold Mining Ball Mill Price/Fine Grinding Ball Mill

Products Description

Benteng Ball Mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

The ball mill is a cylinder tube mill, which is characterized by high grinding efficiency single large capacity, low power consumption and little dust pollution. It is commonly used in closed-circuit milling and open flow milling in the field of cement, fly ash, a variety of non-metallic materials dry milling production.

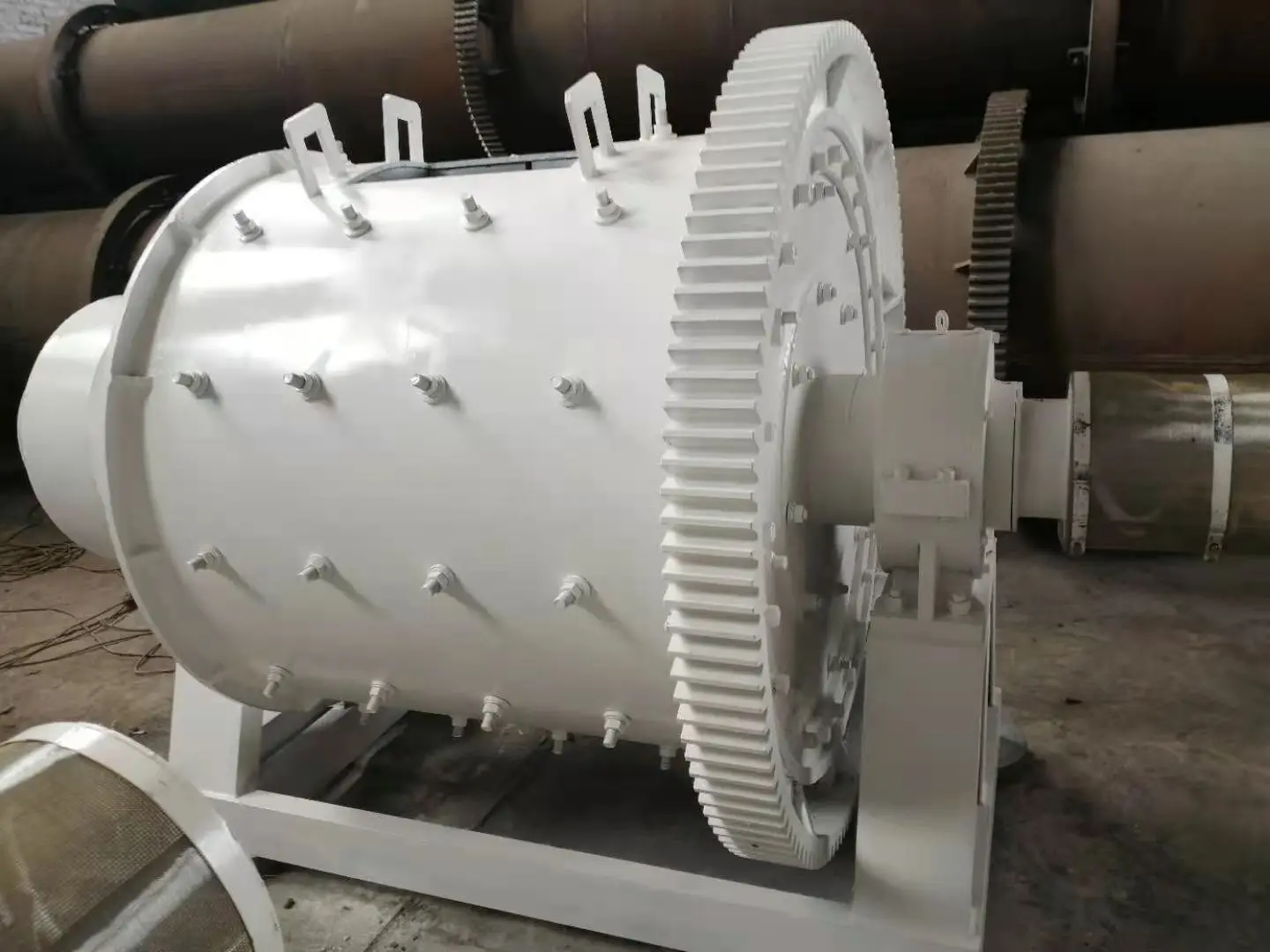

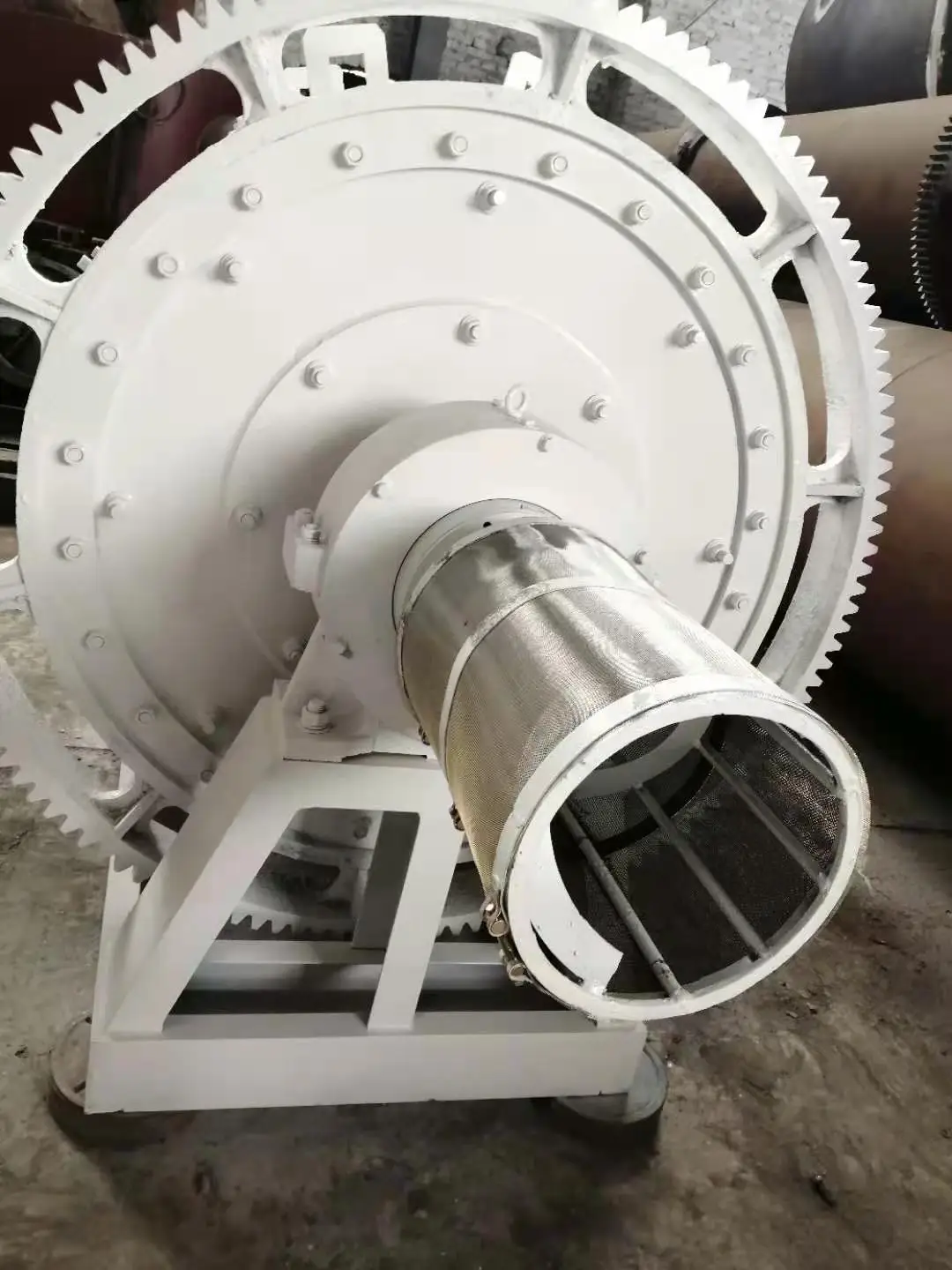

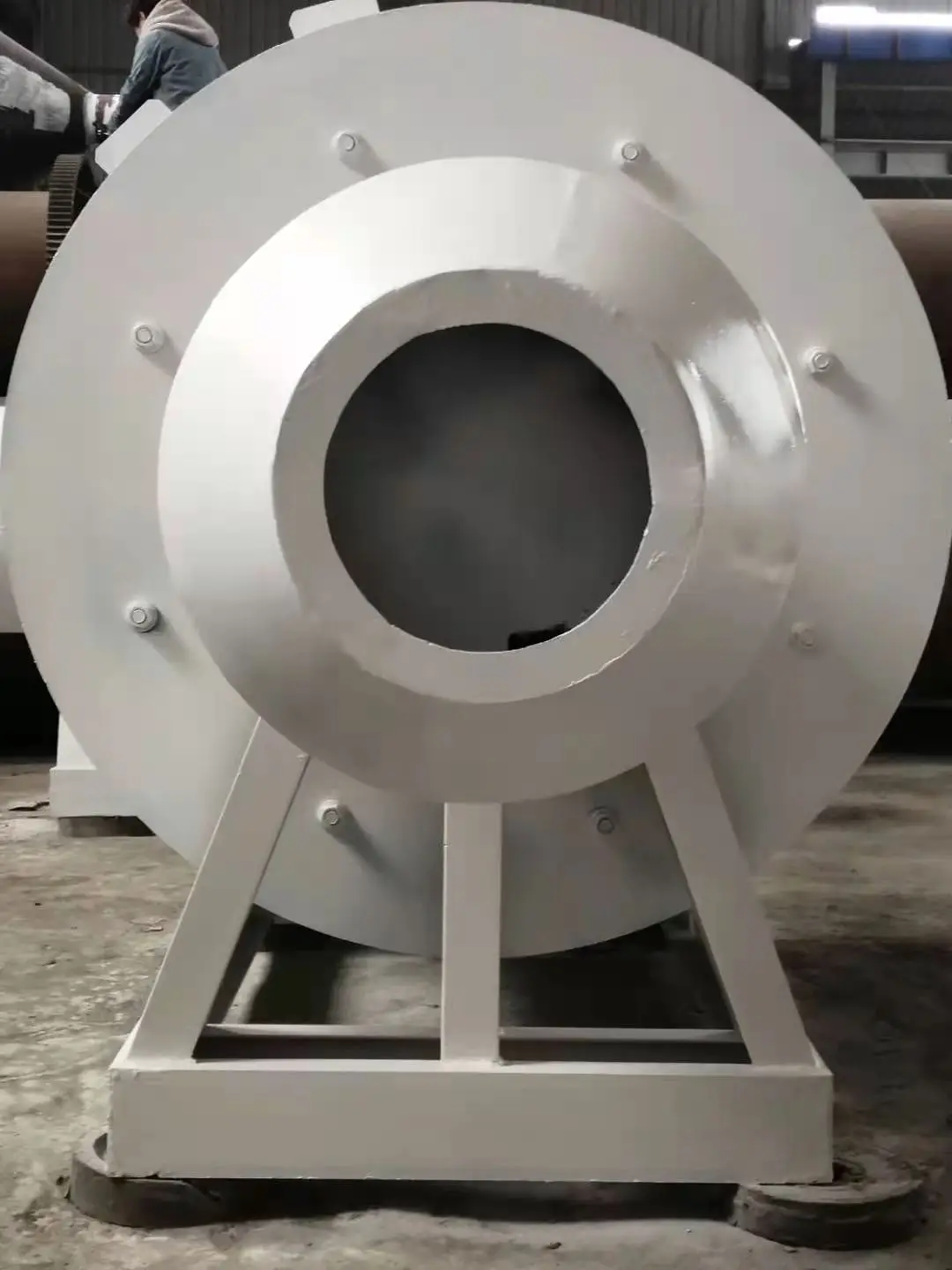

Details Images

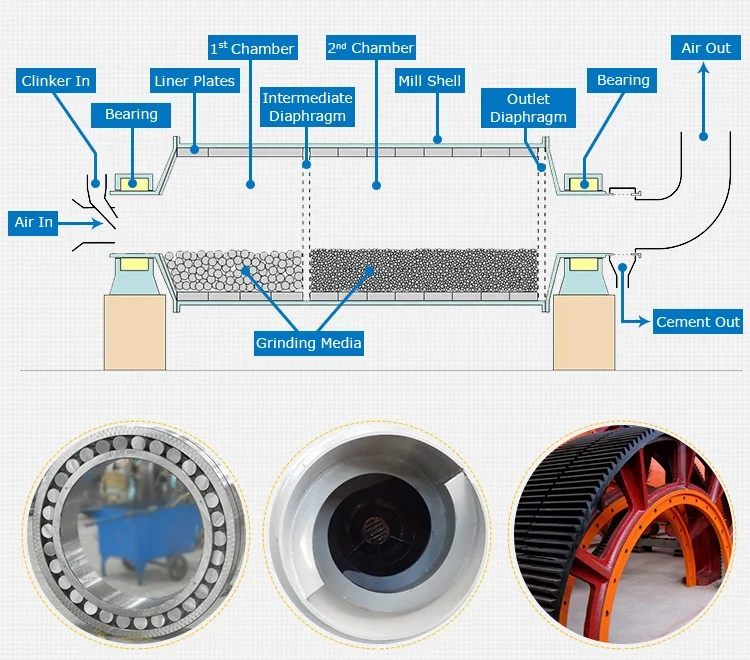

structure of ball mill

Working Principle

The ball mill is horizontal cylindrical rotation device, driving by brim gearwheel, there are two chambers and grid. Material goes into the first chamber through the feeding inlet, inside the first chamber, there are stage liners and ripple liners as well as steel balls with various kinds. The shell rotates which generates eccentricity, this force brings balls to a certain height and then balls drop down by gravity, which will impact and grind the material. After the primary grinding in the first chamber, material goes into the second chamber through segregate screen, in the second chamber, there are fiat liners and steel balls, after the secondary grinding, material is discharged through the discharge screen.

Features about our products

This Ball mill machine changes the intrinsic grinding mill structure

Its body and ground plank are an integral whole. So when fixing, it can be lowered on a plane surface once only

Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%.

The intrinsic grille pattern forcing evacuation is instead by over fall pattern controlling one. This can improve the milling of the granule and the quantity dealt with is reduced by 15-20%.

Product Paramenters

Model | Cylinder Rotating Speed (r/min) | Ball weight (t) | Feeding Size (mm) | Discharging Size (mm) | Capacity (t/h) | Power (kw) |

900×1800 | 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 |

900×3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

1200×2400 | 35 | 4.6 | ≤25 | 0.075-0.6 | 1.6-5.8 | 37 |

1200×4500 | 35 | 5.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

1500×3000 | 29 | 9 | ≤25 | 0.074-0.4 | 2-7 | 75 |

1500×5700 | 29 | 17 | ≤25 | 0.074-0.4 | 3.5-6 | 110-130 |

1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 |

2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 30-50 | 245 |

2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 40-60 | 320 |

2700×3600 | 20.7 | 40 | ≤25 | 0.074-0.4 | 45-80 | 430 |

2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 50-90 | 430 |

2700×13000 | 20.7 | 60 | ≤25 | 0.074-0.4 | 50-90 | 630 |

Paking & Delivery

Packing

We will load different sizes of packing according to different machine sizes, and the normal packing is in wooden cases. If exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to the customer's special requirements.

We will load different sizes of packing according to different machine sizes, and the normal packing is in wooden cases. If exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to the customer's special requirements.

Delivery

We are based on the actual needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt of customer deposits began production, regardless of the size of the equipment we can deliver the goods in two weeks, delivered the balance after delivery.

We are based on the actual needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt of customer deposits began production, regardless of the size of the equipment we can deliver the goods in two weeks, delivered the balance after delivery.

FAQ

Q: If I don't know how to operate this machine? How can I do?

A: Our machine has been tested OK and fully assembled before shipping, customer just needs to make2~4 hours wear-in and then can work.

Q How can I get the price?

A We usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.

Q :What is your term of delivery?

A :We accept EXW, FOB Qingdao. You can choose the one which is the most convenient or cost effective for you.

Best quality vegetable spiral type oil press/ vegetable seeds edible oil presses.

Q: Can I be a distributor of Benteng Machine?

A: Of course you can.

Q:What are the benefits of being a Benteng distributor?

A: - Special discount .

- Marketing protection.

- Supporting of marketing development

- Point to point technical supports and after sales services.

Q: How can i become a distributor of Benteng?

A: Contact us immediately for further details by sending us an inquiry.

A: Our machine has been tested OK and fully assembled before shipping, customer just needs to make2~4 hours wear-in and then can work.

Q How can I get the price?

A We usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.

Q :What is your term of delivery?

A :We accept EXW, FOB Qingdao. You can choose the one which is the most convenient or cost effective for you.

Best quality vegetable spiral type oil press/ vegetable seeds edible oil presses.

Q: Can I be a distributor of Benteng Machine?

A: Of course you can.

Q:What are the benefits of being a Benteng distributor?

A: - Special discount .

- Marketing protection.

- Supporting of marketing development

- Point to point technical supports and after sales services.

Q: How can i become a distributor of Benteng?

A: Contact us immediately for further details by sending us an inquiry.

Our Service

Pre—sale service

2.We will prepare packing and shipment according to customers' need in advance.

3.Testing the machine and making video for customers' checking.

1.We provide pre-sales service in various forms, making investment budget, manufacturing, planning, so that

customers can make a reasonable plan with less cost.

2.We will first check customers' goods and goods size, then we will recommend suitable machine to meet customers' requirement..

3.We will recommend and offer machine according to customers' use and purchase budget.

customers can make a reasonable plan with less cost.

2.We will first check customers' goods and goods size, then we will recommend suitable machine to meet customers' requirement..

3.We will recommend and offer machine according to customers' use and purchase budget.

In-sale service

1.We will supply each manufacturing step photo for customer checking on time.

1.We will supply each manufacturing step photo for customer checking on time.

2.We will prepare packing and shipment according to customers' need in advance.

3.Testing the machine and making video for customers' checking.

After-sale service

1.We will guarantee the machine quality for 1 year.

2.We provide free training and answer customers' questions on technology in time.

1.We will guarantee the machine quality for 1 year.

2.We provide free training and answer customers' questions on technology in time.

CONTACT US

VIEW MORE

YOU MAY LIKE