New fine Raymond mill with superior quality

- $99999.00 / 1 - 9 sets

$5000.00 / >=10 sets - 1 set

- Henan Yuhong Heavy Machinery Co., Ltd.

- Henan, China

- Mr Tomy Feng

| port: | Qingdao | brand: | Henan Yuhong |

| Motor type: | AC motor | application: | ore, coal, cement |

| After-sales service provided: | On-site installation, commissioning and training | Mechanical test report: | if |

| Video shipment inspection: | if | motor: | Chinese famous brand or as required |

| Showroom location: | Malaysia | Install: | Provide basic drawings, guided by our engineers |

| type: | raymond mill | Applicable industries: | Mining, etc. |

| Output size: | 20-1000 mesh adjustable | Maximum feed size (mm): | 30 |

| Packaging Details: | standard export container | Supply capacity: | 50 sets per month |

| Dimensions (L*W*H): | 5970*4000*5000 | Core components: | Engines, Bearings, Motors |

| Core component warranty: | 1 year | payment terms: | L/C, T/T |

| Capacity(t/h): | 2-25 tons/hour | Maximum feed size: | 30mm |

| Health status: | new | capacity: | 0.5-120 tons/hour |

| Marketing Type: | normal product | color: | according to your request |

| place of origin; place of origin: | Henan, China | weight: | 3800 kg |

| Warranty: | 1 year |

New fine Raymond mill with superior quality

describe

YGM series pulverizer is a new type of mining equipment for producing micropowder and fine powder, widely used in metallurgy, mining, chemical industry, cement, construction, refractory materials, ceramic industry, pharmaceutical and other industries.

advantage

1. HGM series mill has high efficiency (twice that of jet mill, mixed mill and ball mill)

2. The service life of the spare parts of the pulverizer is longer (2-3 times that of the impact mill or turbo mill)

3. The superfine pulverizer has high safety and reliability (there is no rolling bearing and screw in the grinding chamber, and there is no problem of bearing or screw wear)

4. HGM grinder is characterized by high fineness (final particle size: 325-3000 mesh, D97<5 microns)

1. Classifier: The particle size of the final product can be 0.613mm (30 mesh)-0.033mm (425 mesh). Some can reach the fineness of 0.013mm (1000 mesh).

2. Grinding device:Multi-stage sealing is adopted to keep the grinding equipment airtight.

3. Gasket protection measures: the host is protected, easy to replace, and reduces maintenance costs.

4. The spring strengthens the grinding force: Compared with other mills, under the same powder conditions, its production capacity is increased by 10%-20%. Under the action of the high-pressure spring, the compression force of the roller on the material is increased by 800-1200kgf.

5. Blower: Strengthen the fan configuration and frequency conversion speed regulation. According to different material characteristics, fineness, and production requirements, the air volume can be adjusted efficiently to achieve the best operating state and reduce energy consumption.

6. Pulse dust collector: the dust removal effect meets the national dust emission standard; according to the actual needs of customers, pulse bag filter can also be used to realize fast automatic dust removal and higher dust removal efficiency.

click nowCatalog and Ex-Works Price!

application

YGM high pressure overhanging roller mill is suitable for advanced milling of more than 280 materials. Such as: barite, slag, calcite, chalk, limestone, dolomite, kaolin, mica, magnetite, vermiculite, sepiolite, gypsum, graphite, fluorite, phosphate rock, potassium pumice, etc. The moth hardness is less than 9.3 and the moisture is less than 8%. Finished product size 80-425 adjustable.

technical parameter

|

Model |

Roller |

Drum size(mm) |

Ring Size (mm) |

Feed size (mm) |

Powder fineness (mm) |

Capacity (tons/hour) |

Motor power(kW) |

Weight (without motor) (t) |

|

YGM85 |

3 |

270×150 |

830×150 |

≤20 |

0.033-0.613 |

1.2-4 |

twenty two |

8 |

|

YGM90 |

3 |

300×160 |

910×160 |

≤25 |

0.033-0.613 |

2.1-5.6 |

30 |

11 |

|

YGM95 |

4 |

310×170 |

950×170 |

≤25 |

0.033-0.613 |

2.1-5.6 |

37 |

14 |

|

YGM130 |

5 |

410×210 |

1280×210 |

≤30 |

0.033-0.613 |

2.5-9.5 |

75 |

twenty four |

Customized service

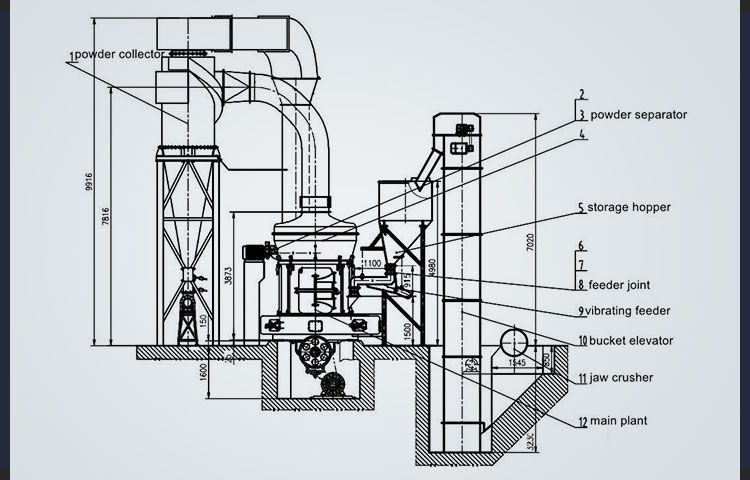

YGM high pressure cantilever roller mill is mainly composed of main machine, classifier, dust collector, powder collector, blower, muffler, hammer crusher (can be replaced by jaw crusher), bucket elevator, soundproof room, storage hopper, vibration feeder The composition of the machine and so on.

1. The bulk material is crushed into the required size by the crusher.

2. The discharged material is lifted to the buffer hopper by the elevator.

3. After that, the material is sent into the mill and crushed by ring rollers.

4. The ground powder rises with the airflow and is collected by the separator as a finished product.

5. The powder that does not pass through the separator falls and is re-grinded.

6. The airflow through the separator enters the blower for recycling.

working principle

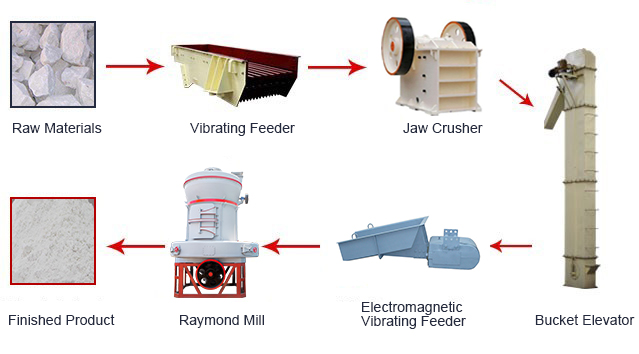

First, the raw material is crushed to the required size by the jaw crusher and lifted to the hopper.

Secondly, the raw material enters the crushing chamber evenly through the electromagnetic vibrating feeder.

Thirdly, the raw material lifted by the shovel is ground into powder between the ring and the roller.

Fourth, the powder is blown to the cyclone collector through the classifier and collected through the discharge valve. Unwanted powders that cannot pass through the classifier will be re-ground into desired powders.

click nowCatalog and Ex-Works Price!

FAQ

Q1: Why choose Yuhong Machinery?

A1: 1. Latest design, CAD calculation and simulation;

2. ISO, BV, SGS, CE quality control manufacturing;

3. More than 30 years of experience, exported to more than 50 countries;

4. The highest standard meets the requirements of operators;

5. World-class quality at an affordable price.

Remarks: Prices will vary depending on different models. Reply to the message and you will get 5% off the price.

Q2: What are the requirements of Raymond Mill for materials?

A2: We, Yuhong, have high standards in choosing materials for Raymond mills.

1. The structural parts are made of high-quality steel plates (ie Q235, Q345);

2. Wear-resistant steel is used for wearing parts (ie ZG35, ZGMn13, 65Mn, 35CrMo, ZG60Si2CrA);

3. Motors, reducers, bearings, belts, and bolts are all top 5 brands in China;

4. Metallurgical properties must be considered during design, cutting, bending, assembly and welding.

Q3: What information do we need to offer you a reasonable model and best quotation?

A3: 1. What is the raw material?

2. What is the maximum feeding particle size of raw materials (mm or mesh number)?

3. Final product size (mm or mesh) and usage?

4. What is the capacity per hour?

Company and factory

Henan Yuhong Heavy Machinery Co., Ltd.

Henan Yuhong Heavy Industry Machinery Co., Ltd. is a joint-stock mining machinery manufacturing enterprise integrating scientific research, production and sales. Its main products include crushing equipment, mineral processing equipment, milling equipment, drying equipment, and kilns. From the perspective of "customer-oriented", we will wholeheartedly provide customers with valuable service models, and make 100% efforts to meet the product needs of different customers.

click nowCatalog and Ex-Works Price!

packaging and shipping

our service

our customers