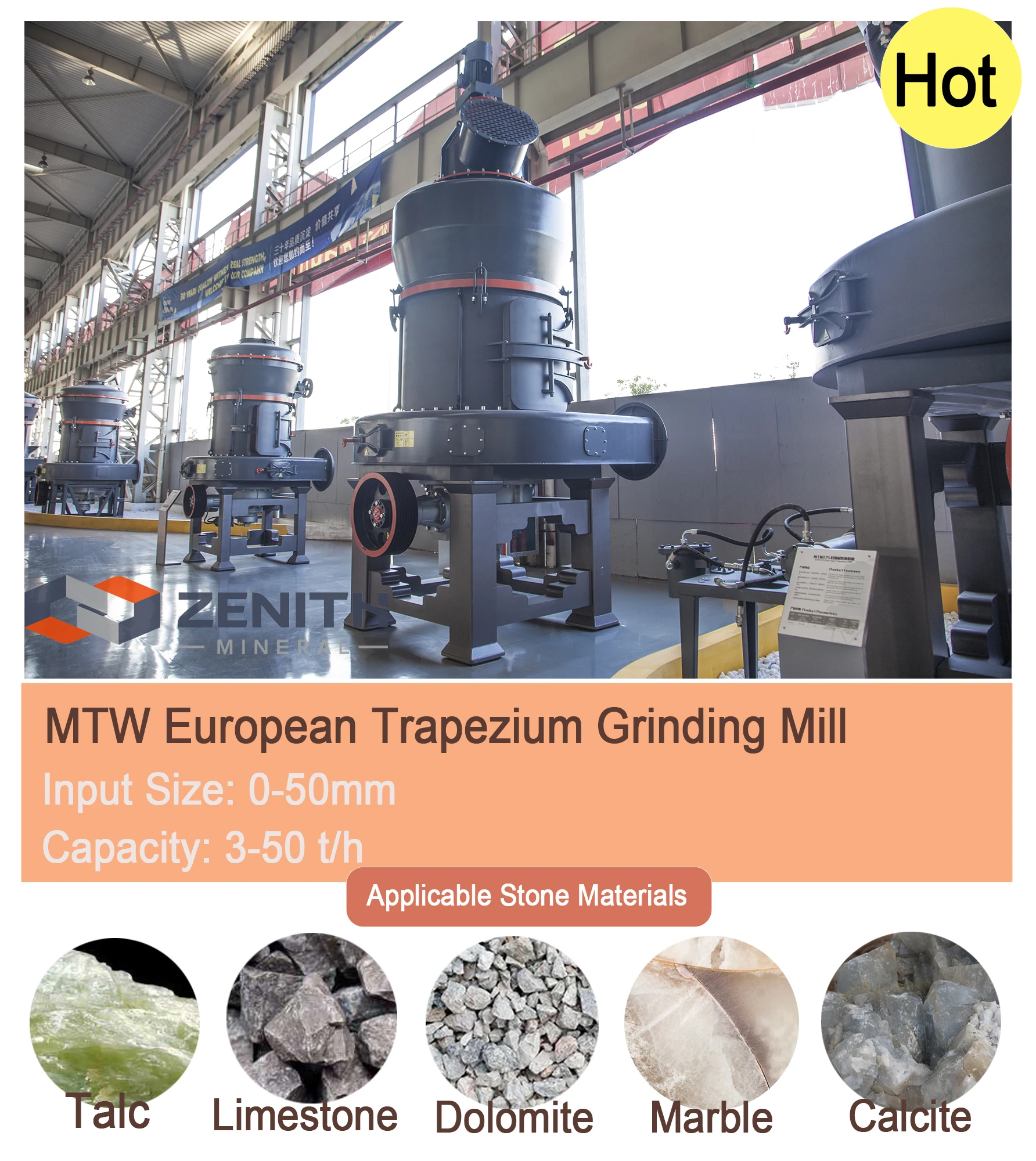

China supplier zenith Natural gypsum grinding plant,gypsum powder making machine

- $10200.00 / 1 - 1 sets

$10000.00 / >=2 sets - 1 set

- Shanghai Zenith Mineral Co., Ltd.

- Shanghai, China

- Ms Carole Wu

| Application: | gypsum powder making machine; | Motor Type: | AC Motor,AC Motor; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Applicable Industries: | Building Material Shops,Construction works ,Energy & Mining; |

| Video outgoing-inspection: | Provided; | Type: | Raymond Mill; |

| Brand Name: | ZENITH; | Package Preview: | ; |

| Showroom Location: | Brazil,Peru,Saudi Arabia,Indonesia,India,Mexico,Russia,Kenya; | Supply Ability: | 30 Sets per Month grinding milling machine; |

| Warranty of core components: | 1 Year; | Guarantee/Warranty: | Quality approvals; |

| Condition: | New; | Marketing Type: | New Product 2020; |

| Spare Parts Supply: | For Whole Year; | Test&Installation: | Engineer Assigned; |

| Port: | Shanghai; | Packaging Detail: | standard container of gypsum grinding plant; |

| Dimension(L*W*H): | gypsum grinding plant; | Place of Origin: | Shanghai, China,Shanghai, China; |

| Certification: | CE,ISO CE CQC; | Capacity(t/h): | 0.5-50TPH,3-50; |

| Weight: | 10t; | After-sale service: | For Whole Using Life; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Video technical support,Online support,Field installation, commissioning and training,Field maintenance and repair service; | Local Service Location: | Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia,Thailand,Malaysia,Kenya,Chile,Colombia,Algeria,South Africa; |

| Machinery Test Report: | Provided; | Warranty: | 1 Year; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; |

Annual 100 Kilotons Natural gypsum grinding plant

Material: Gypsum

Daily Operation: 10h

Input Size: ≤35mm

Finished Product: 325mesh

Equipment: MTW138 Grinding Mill

Project Background

The customer has been doing gypsum industry for a long time, and has used the traditional pulverizer. Later, when he attended the exhibition, he saw ZENITH. After understanding the European version of this product, he finally chose MTW138.

Advantages

1. Energy Saving & Environmental Protection

MTW European Grinding Mill adopts volute design without resistance, which made tangential airflow more smooth and energy consumption lower.

2. High Quality of Finished Product

The mill adopts high-efficiency cage-type powder selecting machine, which can select powder with high precision and efficiency, and prevent the phenomenon of “running coarse powder”.

3. Longer Service Life

The use of thin oil lubrication which is better than traditional oil. The low oil temperature can effectively extend the bearing’s life.

4. Lower Investment

In combination with the requirements of customers, MTW Grinding Mill is used to replace the traditional one, so as to reduce the investment cost in the early stage.

grinding milling machine,grinding milling machine for sale

This type grinding milling machine is mainly used for grinding the material with middle and low hardness, below 6% moisture, and the material should be non-explosion and non-flammability, such as: calcite, chalk,limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite,iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite,barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassiumore pumice, etc

gypsum grinding plant Working principle

1)Raw material which has been crushed to the size specified is elevated into a hopper from which the stuff is loaded. And then through the vibrating feeder ,the materials will transferred evenly and continuously into the grinding milling machine grinding chamber for powder-processing. After this,the ground stuff is carried by the air from the blower into the classifer for regrinding.The set's airflow system is closely sealed up and circulated under the condition of negative and positive pressure.

2) The gypsum grinding plant is driven by rotation of the central axle through decelerator ,with the up end of the axle connecting to a quincunx-rack upon which the grinding equipment is fixed. The whole set equipment turns together with the axle along the grinding ring while the rollers rotate driven by the fractional force .A set of shovel are installed at the lower end of the quincunx-rack.While turning together with the rollers ,the shovels shed the stuff onto the gap between the rollers and the ring ,and that's where the stuff layer forms .The rotating rollers ,while turning together with the ring ,grind the stuff layer into powder.

3) The turning speed of the impeller can be adjusted to the requirement of the fineness of powder products .

4)gypsum grinding plant plays an important role in ensuring the function of the grinder . As the high-speed revolving air current mixed with ground stuff is flown into the cyclone-collector ,the ground stuff is separated from the air-current

Specifications of gypsum grinding plant:

| Name & Model | MTW110 | MTW138 | MTW175 | |

| Ring Roller Number(pcs) | 4 | 4 | 5 | |

| Major diameter of roller(mm) | 360×190 | 460×240 | 520×280 | |

| Inner diameter of roller (mm) | 1100×190 | 1380×240 | 1750×280 | |

| Revolving Speed(rmin) | 120 | 96 | 75 | |

| Revolving Speed(rmin) | <30 | <35 | <40 | |

| Final size(mm) | 1.6-0.045, fineness can reach to 0.038 |

1.6-0.045, fineness can reach to 0.038 |

1.6-0.045, fineness can reach to 0.038 |

|

| Capacity(th) | 3.5-10 | 6.5-15 | 13-20 | |

| Overall dimension(mm) | 8625×7933×8642 | 10920×9470×10227 | 12275×9555×9916 | |

| Main unit motor | Model | Y280M-6 | Y315M-6 | Y355M2-8 |

| Power(kw) | 55 | 90 | 160 | |

| Rotate Speed(rmin) | 980 | 990 | 740 | |

| Classifier speed regulating motor (variable frequency motor) |

Model | Y132M-4 | Y180M-4 | Y200L-4 |

| Power(kw) | 7.5 | 18.5 | 30 | |

| Rotate Speed(rmin) | 1440 | 1470 | 1470 | |

| Centrifugal induced draft fan motor | Model | Y250M-4 | Y315-4 | Y315L2-4 |

| Power(kw) | 55 | 110 | 200 | |

|

A VARIETY OF TRUSTED EXPERIENCE ZENITH has a variety of professional, reliable and efficient crushing lines all around the world. So customers have great confidence in us. |

|

INFINITE BRAND VALUE What ZENITH is doing is customizing economical and suitable production lines for customers and building brand value. |

|

1200,000 SQUARE METERS OF PRODUCITION AREA 6 large-scale manufacturing bases occupy 1200,000 square meters in total. So quick delivery is a matter of course. |

Founded in 1987, ZENITH has attained 124 patents on crushers and grinding mills over the past 30 years and has more than 30 overseas offices or branches built all over the world. Keeping customers in mind, ZENITH never stops the step forward. Wemake evolution on the outside in order to offer you better equipment; we make revolution on the inside in order to offer you better service.