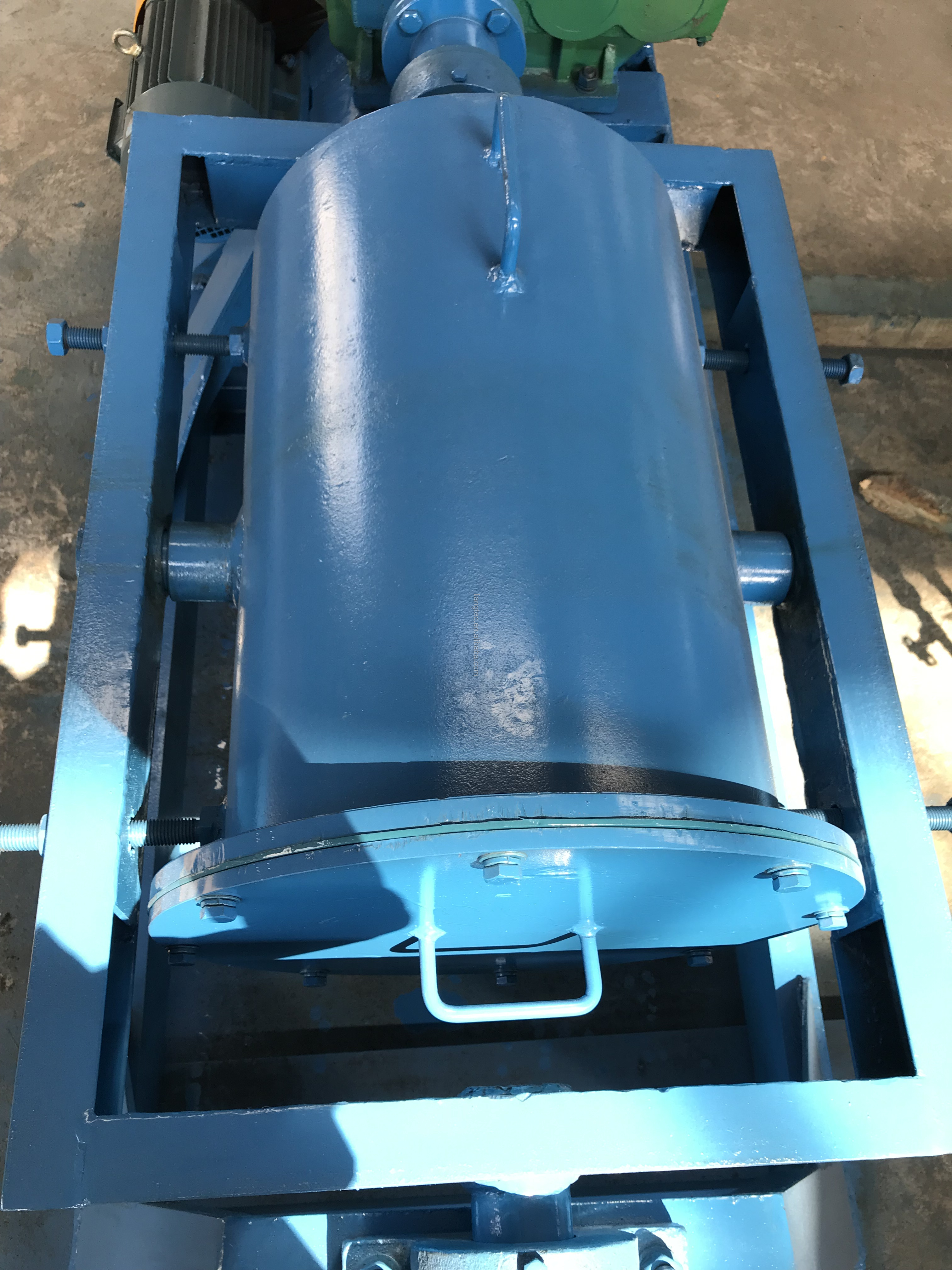

QM400*600 laboratory cylindrical small ball mill for sample grinding

- $1800.00 / 1 - 1 sets

$1500.00 / >=2 sets - 1 set

- Ganzhou Li Ang Machinery Co., Ltd.

- Jiangxi, China

- Ms Emily Woo

| port: | Xi'an, Guangzhou, Shenzhen | Supply capacity: | 500 sets per month |

| Showroom location: | not any | Capacity (tons/hour): | 10 kg |

| Dimensions (L*W*H): | 1.58 cubic meters | Motor power (KW): | 1.5 |

| Local service location: | not any | Packaging Details: | Standard wooden box. |

| Warranty: | 12 months | Motor Type: | AC motor |

| Output Dimensions (mm): | 0.8-0.074mm | payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,e-Checking,Paypal,Credit Card |

| Certification: | CE/SGS/ISO | Health status: | new |

| weight: | 348 kg | After-sales service provided: | Engineers can repair machinery overseas |

| brand: | Li Ang | type: | ball mill |

| maximum. Feeding amount (kg/time): | 50kg/batch | Model: | 460*600 |

| Weight (kg): | 630 | Packaging Preview: | |

| Package dimensions: | 1840*1000*1000 mm | place of origin; place of origin: | Jiangxi, China |

| Cylinder material: | cast steel | Applicable industries: | Manufacturing, Energy & Mining |

Description of Laboratory Cylindrical Ball Mill

The small ball mill is a fully enclosed batch grinding equipment, which can be used for dry grinding or wet grinding. It is used for material crushing in semi-industrial laboratories and small-scale industries such as building materials, fireproof materials, metallurgy, coal, light chemical industry, and agriculture. In the study of the separability of ore, the machine can not only be used as a ball mill, but also meet the requirements of obtaining the required abrasive particle size according to the beneficiation method, and the steel rod can be used as the grinding medium of the rod mill. . It is a grinding equipment suitable for the separation of heavy sand ore in geological experiments.

grind. The material is evenly fed into the initial chamber of the mill by the feeding device through the feeding hollow shaft

Material. The cavity has stepped lining or corrugated lining, and steel balls of different specifications are installed inside.

The rotation of the cylinder generates centrifugal force to bring the steel ball to a certain height. hits after falling

Abrasive material.

After the material reaches the rough grinding in the first bin, it enters the second bin through the single-layer partition.

The silo is embedded with a flat lining with steel balls inside to further grind the material. powder through

The unloading raft completes the grinding operation.

Model | QM-400*600 | ||

Maximum feeding amount (kg/time) | 50 | ||

Capacity (kg/hour) | Output size (mm) | capacity | |

0.8 | 350 | ||

0.3 | 300 | ||

0.2 | 150 | ||

0.15 | 90 | ||

0.074 | 45 | ||

Power (kW) | 15 | ||

Dimensions (mm) | 1650*900*1050 | ||

Weight (kg) | 630 | ||

For the packing of our ball mill, we will use wooden box packing to ensure its safety and stability during international shipping.