cold chamber aluminum alloy die casting machine injection moulding machine

- $129100.00 /set

- 1 set

- Jiangmen Zhenli Machinery Co., Ltd.

- Guangdong, China

- Mr YongXiang Li

| Weight (KG): | 27500; | Applicable Industries: | Manufacturing Plant; |

| Casting Force(kN): | 590kN,590 kN; | Diameter of Bars(mm): | 800mm,800 mm; |

| After Warranty Service: | Video technical support,Online support,Field maintenance and repair service; | Packaging Detail: | wooden pallet,package size 7580*2060*2178mm,in need of 1*40'GP container; |

| Key Selling Points: | High Productivity; | Clamping Force (kN): | 7000kN,7000 kN; |

| machine electric parts: | schneider; | Casting Pressure(MPa): | 117MPa,117 MPa; |

| Local Service Location: | Turkey,India; | Marketing Type: | Hot Product 2019; |

| Machine Type: | Cold Chamber Die Casting Machine; | Ejection Stroke(mm): | 155 mm; |

| Open Stroke(mm): | 650mm,650 mm; | Certification: | CE-RoHS; |

| Port: | shenzhen/gaosha; | machine material: | cast iron; |

| machine color: | blue bases,yellow door,white computer; | Condition: | New; |

| Brand Name: | ZHENLI; | Warranty of core components: | 1 Year; |

| Core Components: | PLC,Motor,Pump; | Warranty: | 12months; |

| Video outgoing-inspection: | Provided; | Min.Thickness of Die Block (mm): | 350 mm; |

| Voltage: | 220V/380V/415V/460V; | Place of Origin: | Guangdong, China; |

| Max.Thickness of Die Block (mm): | 850 mm; | Ejection Force(kN): | 315 kN; |

| Machinery Test Report: | Provided; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Casting Stroke(mm): | 650mm,650 mm; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| machine valves: | yuken,Japan; | Supply Ability: | 30 Sets per Month; |

| machine type: | factory,manufacturer; | Showroom Location: | Turkey,India; |

| Dimension(L*W*H): | 7580*2060*2850mm; |

horizonal continuous casting machine, cold chamber die casting machine,aluminum die casting machine,die casting machine-ZLC-700T.

Advantage

1.Aluminum casting .

2.Aluminum die casting machine .

3.High quality ,adopts precise artificial intelligent computer control .

The die casting machine structure adopts 3-pull rod or C- shaped bracket plus hydraulic elevator device and satisfies requirements for moulds .

|

Item |

Unit |

ZLC-700 |

|

Clamping Force |

KN |

7000 |

|

Die Stroke |

MM |

650 |

|

Die Thickness(Min-Max) |

MM |

350-850 |

|

Platen Size(HXV) |

MM |

1256X1360 |

|

Space Between Tie Bars |

MM |

800X800 |

|

Tie bar Diameter |

MM |

165 |

|

Intensification Injection Force |

KN |

580 |

|

Injection Force |

KN |

215 |

|

Injection Stroke |

MM |

650 |

|

Plunger Diameter |

MM |

80,90,100 |

|

Shot Weight |

kg |

4.2,5.8,7.3 |

|

Casting Pressure |

Kgf/cm² |

1154.912.738 |

|

Casting area |

cm² |

545,690,858 |

|

Max Casting Area Under 40Mpa |

cm² |

1472 |

|

Shot Injection Position |

MM |

0-250 |

|

Plunger Penetration |

MM |

290 |

|

Ejector Force |

KN |

315 |

|

Ejector Stroke |

MM |

155 |

|

Hydraulic Working Pressure |

Kgf/cm² |

140 |

|

Driving Motor |

HP/KW |

37 |

|

Hydraulic Oil Tank Capacity |

L |

1050 |

|

Machine Weight |

KG |

27500 |

|

Machine Dimensions(L x W x H) |

MM |

7580×2060×2800 |

The injection system is equipped with large diameter logic valves and precise flow control valves,improves injection response,decreases oil pressure vibration and provides precise 4-stage shot adjustment.

Adopts high and low pressure twin pump with high performance and low noise,saves energy consumption and improves production efficiency .

Adopts automatic concentrated lubrication system ,directly sets lubrication for times of machine operation and improves service life of the machine and decrease repair .

The planetary wheel system adopts oil motor to drive the gear mould adjusting machine structure which is easy to operate ;owns intelligent automatic mould adjusting program ,precisely calculates the mould locations ,which is convenient for mould replacing and improves efficiency .

The hydraulic ejector is convenient for control with adjustable ejecting speed .

The hydraulic main system adopts double proportional control ,which is convenient for adjusting the pressure and speed of every movement in the operation .The outlay precise suction filter ensures the hydraulic system of cleanness and decreases weariness of the hydraulic components .

Appliances control:

1.Adopts precise artificial intelligent computer control,can control and supervise the data

and status of every movement,which is convenient for operation and maintenace .

2.The large screen LCD monitor can realize conversion between Chinese and English.

3.Its powerful memory can store 100 sets of moulding data ,such as the time,times,speed,pressure,traveling distance,mould thickness,options,etc

4.Has self-check and alarm functions to failures of computer hardware,and display function of mechanical failures,which is convenient for mechanical failure removal .

5.Mould closing adopts high precision E-ruler positioning test,which can control the precise distance to 0.1mm.

when the machine arrival your destination port,we will appoint one technician go to your factory, commissioning the machine for you. until the machine normally produce your product,generally, 3days is ok. by the way, our technician can training your worker for free.

Our Target:

To Become A Gobally Famous Brand in the Line of Die Casting Machine.

established in 2002 and with more than ten years of development,ZHENLI machinery CO.,LTD,has owned 20000square meters production bases. ZHENLI is a high-tech company specializing in the R&D, production,sales and services. the main product of the company include "ZL" hot chamber die casting machine, ZLC cold chamber die casting machines and the peripheral devices.

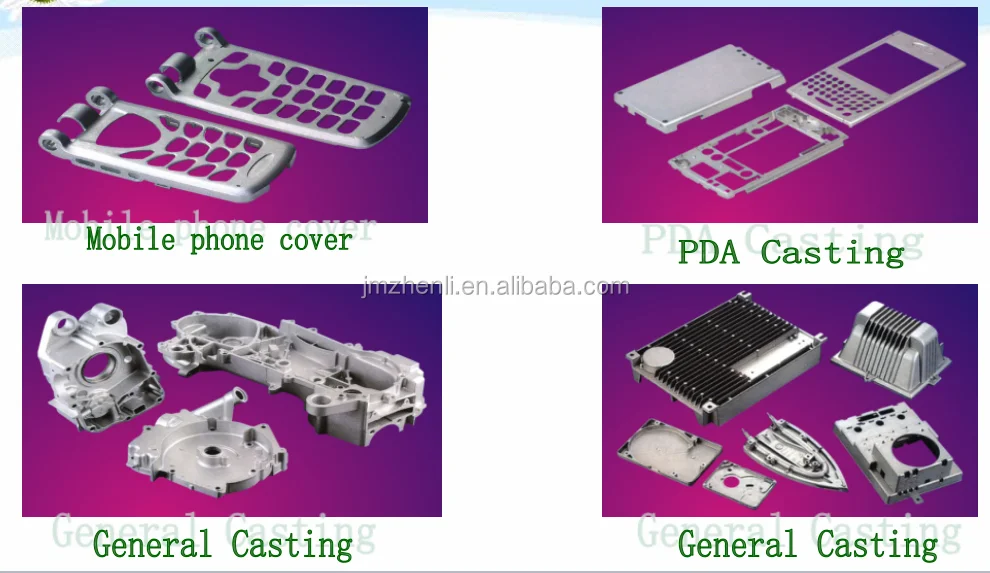

adhering to the business philosophy of "keep improving and cast performance" and the spirit of "Exploration,innovation,pioneering and integrity",zhenli is dedicated to the development of precision computerized cold /hot chamber die casting machines which are widely applied in sectors of toys,home supplies,building hardware,industrail parts,telecommunication,auto parts and electronics and satisfy the technical requirements for production of castings.

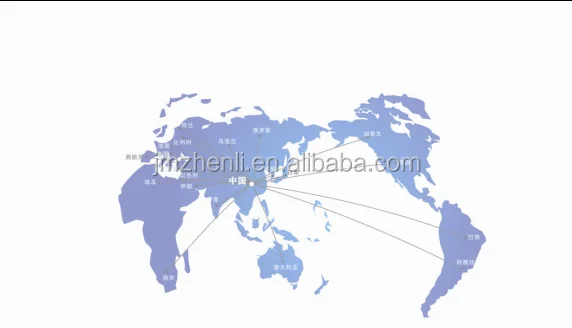

Based on our technical strength,professional equipment and R&D and design teams as well as advanced technologies ,we are able to manufacture series of cold/hot chamber die casting machines with stable performance,smooth system operation,fast injection speed and short pessutization time,with our advanced technologies,reliable product quality,excellent presales and aftersales services.Zhenli machines have won reliance from customers both at home and abroad and Zhenli has become a best-selling brand in the market,Zhenli machines have been sold to more than 30 provinces in China and 30 countries and regions including Europe,South America,Southeast Asia and Middle East, and Zhenli has become one of the biggest die casting machine exporters.

Other Products

-

hot chamber die casting machine for making zamak button$23850.00 / set

hot chamber die casting machine for making zamak button$23850.00 / set -

hot chamber die casting machine zamak moulding injection machine$23850.00 / set

hot chamber die casting machine zamak moulding injection machine$23850.00 / set