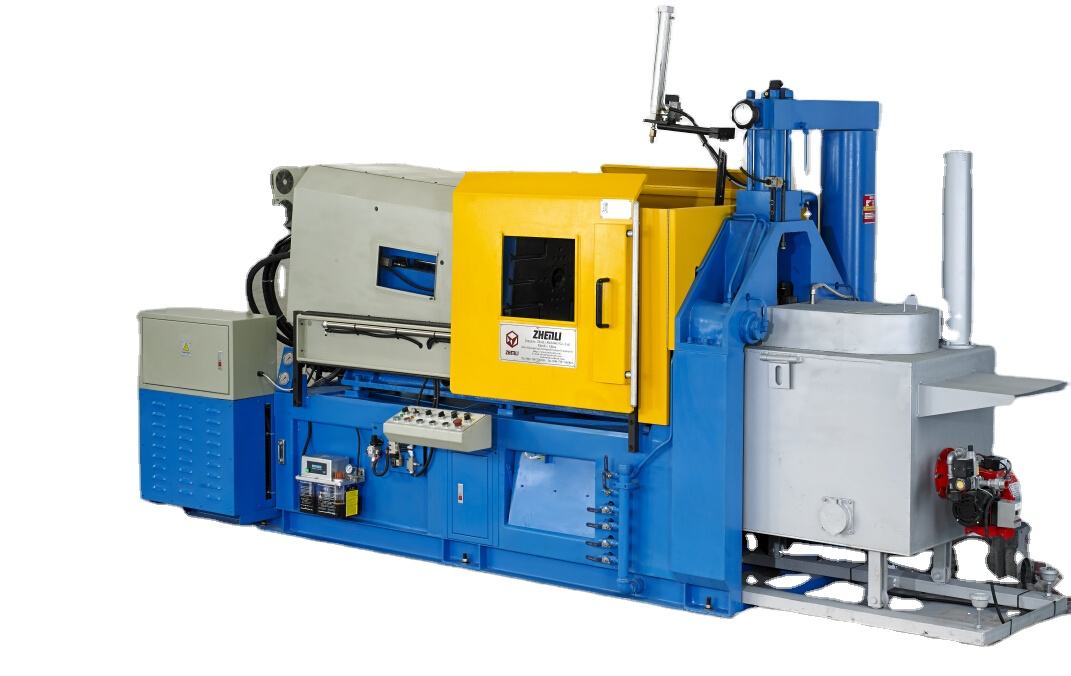

hot chamber die casting machine for making zamak button

- $23850.00 /set

- 1 set

- Jiangmen Zhenli Machinery Co., Ltd.

- Guangdong, China

- Mr YongXiang Li

PRODUCT DETAIL

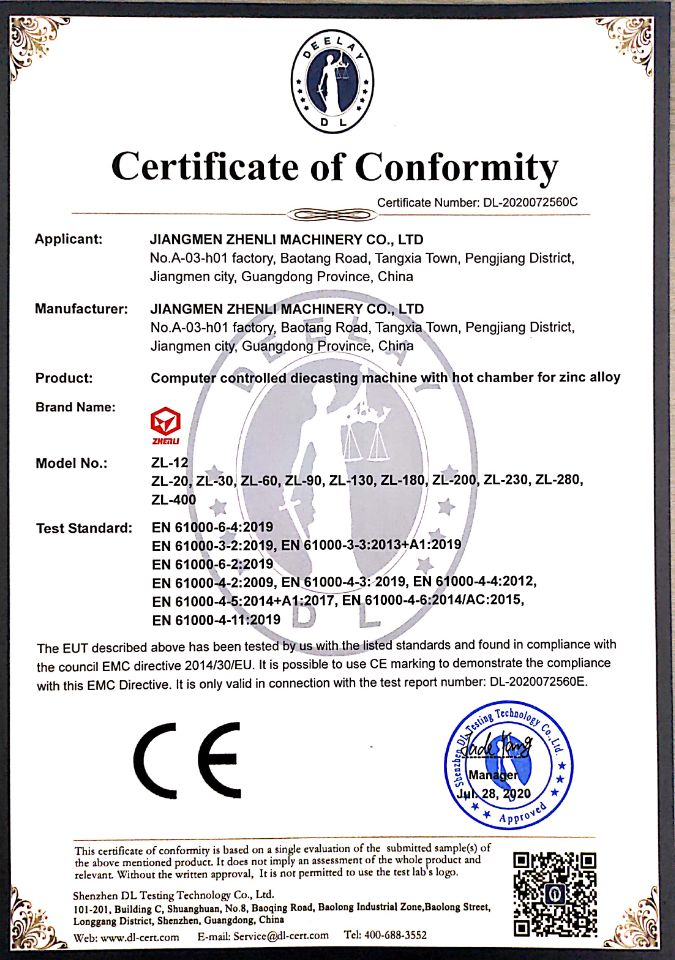

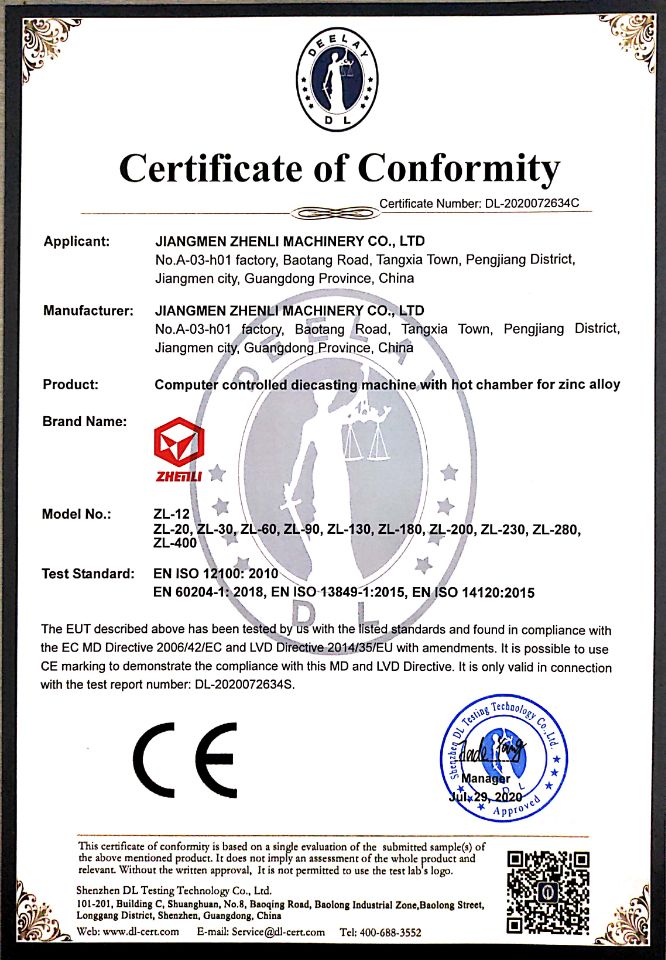

| Automatic Grade: | Full-Auto; | Power (kW): | 7.5; |

| Dry cycle: | 5s; | Ejection Stroke(mm): | 55 mm; |

| Certification: | CE, ISO; | Showroom Location: | Egypt,Turkey,Philippines,Brazil,Indonesia,Pakistan,India,Mexico,Russia,Argentina,Colombia,Algeria,Bangladesh,Uzbekistan,Malaysia; |

| Die-locking Force (kN): | 300kN; | Inner Space Between the Bars (Horizontal)(mm): | 275mm; |

| Max.Thickness of Die Block (mm): | 305 mm; | Machine Type: | Hot Chamber Die Casting Machine; |

| Payment Terms: | L/C,T/T; | Control system: | PLC; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Type: | 30T; |

| Supply Ability: | 20 Sets per Month; | Marketing Type: | New Product 2020; |

| Chamber: | hot chamber die casting machine; | After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Weight (KG): | 2600; | Warranty: | 1 Year; |

| Video outgoing-inspection: | Provided; | Suitable material: | zinc / lead; |

| Local Service Location: | Turkey,Brazil,Indonesia,India,Malaysia,Argentina,Colombia; | Oil tank capacity: | 12.5L; |

| Applicable Industries: | Manufacturing Plant; | Brand Name: | ZHENLI; |

| Injection Force(kN): | 42kN; | Condition: | New; |

| Injection Stroke(mm): | 120mm; | Inner Space Between the Bars (Vertical)(mm): | 275mm; |

| Min.Thickness of Die Block (mm): | 100 mm; | Machinery Test Report: | Provided; |

| Voltage: | customized; | Packaging Detail: | wooden package &1*20GP container; |

| Dimension(L*W*H): | 3320*1400*1800mm; | Key Selling Points: | Automatic; |

| Warranty of core components: | 1 Year; | Package Preview: | ; |

| Technology: | Die Casting Technology; | Place of Origin: | Guangdong, China; |

| Port: | SHENZHEN; | Name: | Zinc Die Casting Machine; |

| Ejection Force(kN): | 35 kN; | Year: | 2021; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Function: | Die Casting zinc; |

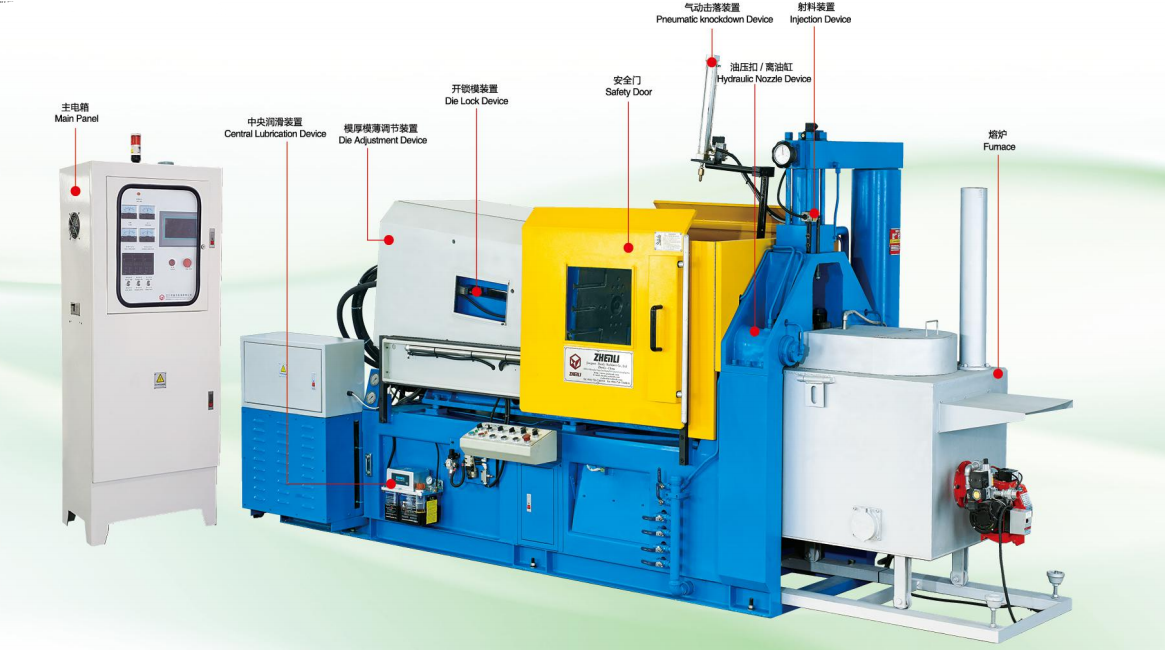

Product Overview

zinc (zamak) / lead hot chamber die casting machine

With competitive technology and comprehensive strength, we present customer with the most suitabletegrated die-casting equipments.

Advantage

1 . easy operation the machine is equipped with an intelligent computer controller , which makes the control system more stable and reliable ; its big liquid crystal screen provides easy operation . furthermore , our self - developed graphical interface makes the parameter setting easier , and convenient for production management .

2 . high stability

piston - type accumulator is used for the beam type injection system , which makes the injection speed high as well as stable . the dry shot speed is bigger than 5 ms thus , the production quality can be secured

3 . high efficiency

provided with fast die camping system , so the production cycle is smaller than others d of the machine . simultaneously , our machines are the unique double proportional hydraulic system greatly improves the response speed

PRODUCT SPECIFICATIONS

No | ITEM | UNIT | ZL-30 |

1 | Locking force | kN | 300 |

2 | Die stroke | mm | 190 |

3 | Ejection force | kN | 35 |

4 | Ejection stroke (MAX) | mm | 55 |

5 | Die height (min-max) | mm | 100-305 |

6 | Tie bar diameter | mm | 45 |

7 | Space between tie bar | mm | 275*275 |

8 | Injection position | mm | 0,-40 |

9 | Plunger stroke | mm | 120 |

10 | Traverse stroke | mm | 180 |

11 | Injection force (MAX) | kN | 42 |

12 | Plunger diameter | mm | 36/40 |

13 | Max shot weight | kg | 0.58/0.68 |

14 | Hydraulic pressure | MPa | 12.5 |

15 | Motor power | kw | 7.5 |

16 | Crucible capacity (Zn) | kg | 260 |

17 | Accumulator capacity | L | 12.5 |

18 | Diesel furnace consumption | kg/h | 3.5 |

19 | Electric furnace consumption | kw | 25 |

20 | Oil tank capacity | L | 190 |

21 | Machine diameter ( L*W*H) | mm | 3320*1400*1800 |

22 | Referential machine weight for uplifting | kg | 2600 |

PRODUCT CONFIGURATION

High-strength and efficient die clamping machanism

1. Hinge and clamping mechanism of double toggle machine, high-strength ductile iron template with CNC precision machining, strong and durable.

2. Anti-wear hard chrome high tensile alloy steel guide post, durable and reliable.

3. The low-pressure protection program ensures the safety of the mold.

4. High-precision electronic ruler position detection, precise control of the clamping stroke.

5. Automatic front and back movement tilt mold clamping system, fixed nozzle or off-mouth die casting can be selected.

6.Large mold capacity space, realize automatic adjustment of mold thickness.

3. The low-pressure protection program ensures the safety of the mold.

4. High-precision electronic ruler position detection, precise control of the clamping stroke.

5. Automatic front and back movement tilt mold clamping system, fixed nozzle or off-mouth die casting can be selected.

6.Large mold capacity space, realize automatic adjustment of mold thickness.

7. Equipped with hydraulic automatic lifting mold base function, can choose center or offset shooting position

8. The computer cooperates with the oil circuit to realize four-stage mold locking to ensure the protection of the low pressure mold locking stage. Effectively protect templates and molds.

1. The nozzle, nozzle body, gooseneck and crucible are made of high-temperature hot working materials, which are durable and

reliable. 2. The nozzle body and gooseneck are heated by electric heaters, which are safe and durable. Keep the temperature stable

to avoid plugging the mouth and the production of defective products due to temperature changes.

reliable. 2. The nozzle body and gooseneck are heated by electric heaters, which are safe and durable. Keep the temperature stable

to avoid plugging the mouth and the production of defective products due to temperature changes.

The unique dual-proportional hydraulic integrated system adopts independent flow and pressure two sets of proportional valves, so

that the speed and pressure of mold opening, mold clamping, thimble, and snapping can be adjusted at will.

that the speed and pressure of mold opening, mold clamping, thimble, and snapping can be adjusted at will.

The water-cooled oil circuit cooler has high cooling efficiency and can maintain a specific oil temperature and viscosity to

ensure stable machine performance.

ensure stable machine performance.

Japanese electronic stove has stable firepower adjustment and high safety performance.

Using world brand (Yuken, Rexroth, Vickers) hydraulic components, stable and reliable work, long life.

The automatic centralized lubrication system directly sets the lubrication of the reaming operation times.

Electrical Control Parts

1 . The integrated and separated electrical cabinets are available , easy for arrangement

2 . The intelligent computer is adopted to control and monitor the data and status of each action , easy for operation and maintenance

3 . The big liquid crystal screen can realize the conversion of multiple languages such as Chinese , English , Russian , and so on

4 . The powerful memory can store molding data , such as time , times , speed pressure , stroke , mold thickness , options and so on .

5 . The control system is equipped with self-check and failure alarm function which is convenient for troubleshooting

6 The input and output monitoring function s provided with LED indicators

7 Die clamping system is equipped with electric ruler which is used for position test , and the accuracy can be reached 0.1mm

8 The production time and batch are recorded automatically so that the machine can stop working automatically based on the set quantity.

servo system:

The energy saving rate of each shot is very high, 40%-70% higher than the traditional machines.

Servo system can response quickly, and the pressure change between 0 and 100% can reach 30ms, which can improve productivity by5%-12%.

Servo system can lower the hydraulic temperature and then reduce the use of cooling water by 30%, which can prolong the working lifeof hydraulic parts, reduce the noise and improve your working environment.

SALES AND SERVICE NETWORK

Company Profile

About us:

Located in Jiangsha Industrial District of Jiangmen City , China ' famous motorcycleproduction base , Jiangmen Zhenli Machinery Co , Ltd is a high-tech company specializingin R & D , design , production , and after-sale services . Since its foundation in 2002 , aftera decade ' s development and dedication , Zhenli has developed into a modern factorywith imported CNC machining center , gantry milling , planer , grinder , and other advancedequipment . The main products of Zhenli include " ZL " series of hot chamber die castingmachines , ZLC " series of cold chamber die casting machines , servo die castinmachines , real-time control die casting machines , magnesium alloy die casting machines ,and peripherals , etc .

Adhering to the business philosophy of Keeping Improvement and HighPerformance " and the faith of Innovation and Integrity " , in pursuit of high qualityreliance and reputation , Zhenli always places more emphasis on the technology andmanagement . Because of its advanced technology , high quality and effective managementZhenli' s hot chamber as well as cold chamber die casting machines have won the trustand love of our clients at home and abroad . Besides , our machines are widely appliedin the sectors of toys , appliances , building materials and hardware , industrial parts , autoparts , electronics , etc In a word , our machines almost can satisfy all kinds of production ofcastings .

Apart from professional equipment , a qualified R & D team , the stable performance andreliable quality of machines , Zhenli will provide excellent pre-sale and after-sale services .which makes Zhenli become a best-selling brand in the domestic and extemal market . Sofar , in addition to 30 provinces or cities in China , Zhenli' s die casting machines have beensold to more than 50 countries in Europe , South America , Africa , Southeast Asia and theMiddle East . and so on .

We love die casting machines , so we try to be professional ; we are professional , so weare excellent . It is our good hope to promote , by joint effort , both business and friendship toour mutual benefit.

CNC machining workshop

Tosh*ba processing machine

Inspection table and some processing machines

cold chamber die casting machine workshop

hot chamber die casting machine workshop

peripheral devices and cabinet workshop

Exhibition in columbia

Exhibition in India

Exhibition in Russia

Exhibition in Uzbekistan

FAQ

Q1: Does it works auto?

Q3: How can I choose the suitable machine?

A3: Our machines have many types. Different type depends on your product size. The bigger product you make, the bigger machine you need.

A1:It can work full auto by equipped the preipheral devices, such as ladle, sprayer, extractor, ect

Q2: What kind of the furnace use for?

A2: We have 3 kinds of the furnace, electric, natural gas and diesel. We use the Japaness brand of the burner and we can customized the electric voltage for different countries.

Q4: I have the mold, but different with your size, can I use it?

A4: Yes, we are the manufacturer, we have the processing machines. We can following your design to process our machine parts.

SIMILAR PRODUCTS

VIEW MORE

YOU MAY LIKE