Competitive In-Line Pasteurizer for Juice/Beverage and Milk UHT Milk Pasteurizer

- $2000.00 /unit

- 1 unit

- Hangzhou Huihe Machine Equipment Co., Ltd.

- Zhejiang, China

- Mr Awen Wu

| After Warranty Service: | Video technical support, online support | brand: | high |

| Showroom location: | not any | After-sales service provided: | Engineers can repair machinery overseas, video technical support |

| Marketing Type: | Hot Products of 2019 | Processing Type: | milk |

| application: | Milk sterilization, fruit juice sterilization, beverage sterilization, wine sterilization | construction area: | 0.8㎡ |

| port: | Ningbo or Shanghai Port | product name: | used food processor for sale in Hangzhou |

| heating method: | steam heating | Sterilizer temperature: | 115-135℃ |

| Warranty: | 2 years | Packaging Preview: | |

| Dimensions (L*W*H): | 0.8*1.0*1.5M | Sterilization time: | 4-6 seconds |

| Processing: | Sterilizer | strength: | 9~30KW |

| Core Components Warranty: | 2 years | Applicable industries: | Hotels, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Retail, Food Stores, Construction Works, Food and Beverage Stores |

| place of origin; place of origin: | China | Certification: | Chief Executive |

| weight: | 500KGS | Local service location: | not any |

| Supply capacity: | 1200 units per year | capacity: | 0.5-1T/h |

| Voltage: | 220/380/420V | Health status: | new |

| Packaging Details: | Standard wooden box or according to customer requirements | payment terms: | L/C,D/A,D/P,T/T,Western Union |

| Core components: | Electric motors, pressure vessels, pumps, pipes and valves | Mechanical test report: | if |

| Material: | Stainless Steel 304/316L | Video external inspection: | if |

| steam pressure: | <0.4Mpa |

|

The use of small ultra-high temperature sterilizer

|

|

Small UHT sterilizers are widely used in Fresh milk, soy milk, fruit juice, beverage, soy sauce, wine, ice cream sauce and other fluid materials such as soy milk, fluid medicine.If the homogenizer is set together, it can also be used forhigh viscosity materialSuch as beets and condensed milk.

|

| Features of small ultra-high temperature sterilizer |

|

1. Continuous production, short sterilization time;

2. Short heating time and good product quality;

3. Ultra-high temperature, ideal sterilization effect;

4. Linked with centrifugal pump and high-pressure homogenizer, it has a wide range of applications and is suitable for sterilization of high-viscosity materials.

5. The designed heat exchanger can utilize the waste heat, and the steam consumption is small.

|

| Material and model of small ultra-high temperature sterilizer |

| The material of the small ultra-high temperature sterilizer of Hangzhou Huihe Machinery Manufacturing Co., Ltd. is generally SUS304 or SUS316, if the customer has no special requirements.

|

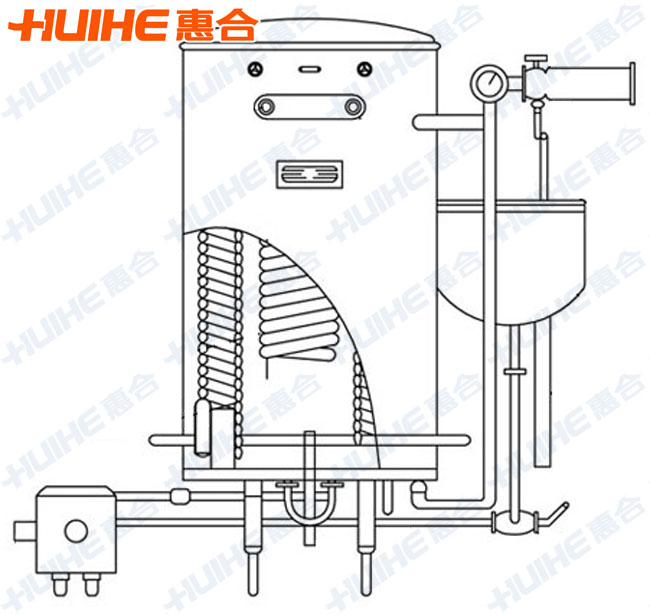

| Picture of small ultra-high temperature sterilizer |

|

|

| Technical parameters of small ultra-high temperature sterilizer | |||||||||||||||||||||||||||||||||||||||||||||

notes:

1. The parameters of the UHT sterilizer sterilization equipment in the picture are standard configuration.Please let us know if you have any specific requirements.

2. These process parameters need to be provided when selecting UHT: material properties, yield, sterilization conditions, specific requirements, etc.

|

Other sterilizers

| overweightMilk sterilizer packaging before delivery |

|

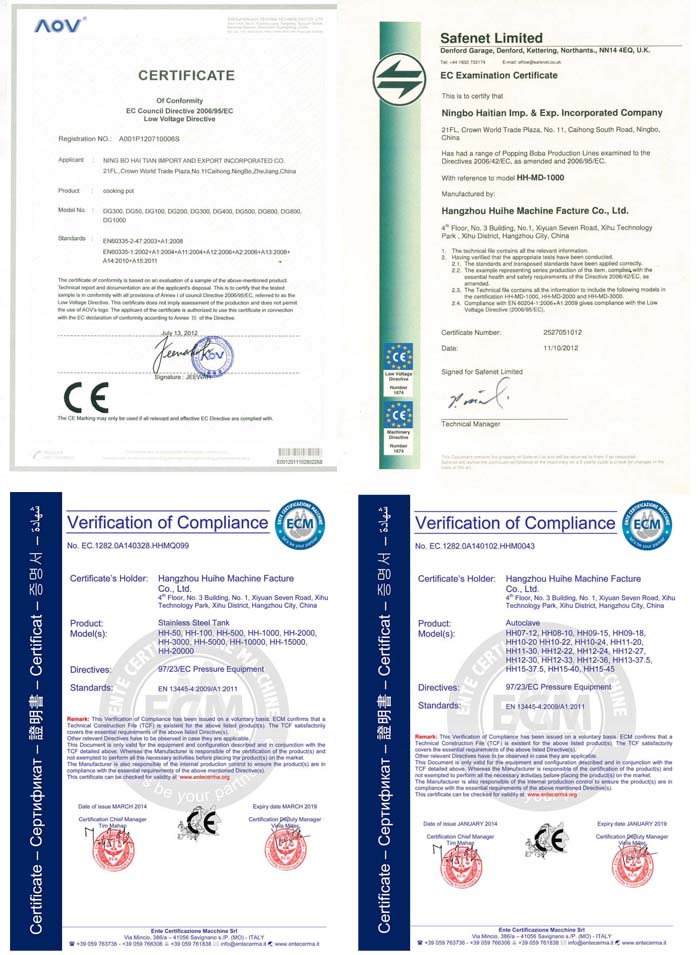

| Certification and strength display |

Hangzhou Huihe Machinery Factory is committed to designing and manufacturing all kinds of stainless steel containers. We can design all kinds of stainless steel vessels, jacketed kettles, autoclaves, milk cooling tanks, fermentation tanks, etc. according to customer requirements. The equipment conforms to hygiene standards and effectively protects people's health.

Huihe Company not only has a professional overseas sales team, but also has departments such as network, sales support, technology research and development, etc., which can provide turnkey projects for the design and manufacture of entire production lines such as milk production lines, juice production lines, tea production lines, etc. Our core value is "serving small and medium-sized food enterprises and benefiting the public", and our products have been exported to all over the world for 15 years. We are trusted by users in the food and beverage industry. Jacketed kettles, sterilization equipment, reaction tanks, fermentation tanks, etc. enjoy a high reputation in the field of food machinery.

Since our establishment in 2005, we have served our customers with good pre-sales support and after-sales service. Our tenet is "guaranteed quality, complete variety, competitive price and prompt delivery". We adhere to the vision of "integrity, pragmatism and win-win", and provide the best quality and service.

|