Laser shock shot peening solution for metal surface hardening repair

- $188000.00 /piece

- 1 piece

- Wuhan Questt Asia Technology Co., Ltd.

- Hubei, China

- Ms Questt Laser

| payment terms: | L/C,T/T,Western Union | port: | Shanghai/any |

| Supply capacity: | 6000 acres per year | Warranty: | 2 years |

| Laser source brand: | Quest | CNC or not: | Yes |

| place of origin; place of origin: | Hubei, China | After-sales service provided: | On-site installation, commissioning and training |

| Main selling point: | high rigidity | Packaging Details: | wooden packaging |

| Health status: | new | Laser Type: | Q-switched laser, Q-switched |

| Applicable industries: | Building material stores, manufacturing plants, mechanical repair shops, construction works | Applicable materials: | Metal |

Laser shock shot peening solution for metal surface hardening repair

LSP system configuration:

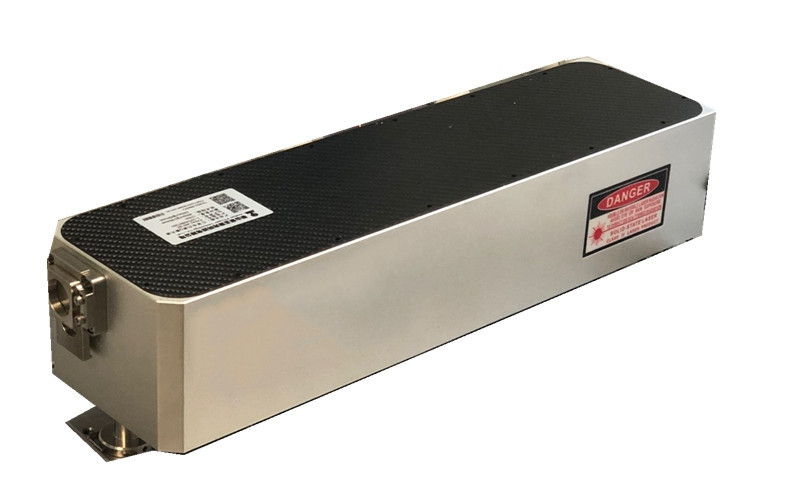

1. Lamp-pumped high-energy electro-optical Q-switched laser

2. Laser shock strengthening control system

3. Six-axis automatic robot

4. Special light guide arm and flexible optical path system

Laser sources for laser shock hardening

Hercules series lamp high-energy electro-optical Q-switched laser is a laser with high beam quality, high energy, high stability, high energy and high conversion efficiency.

| Hercules 1000 | Hercules - 2000 | ||||

Output characteristics | ||||||

wavelength | 1064nm/532nm | |||||

Pulse output | (-S) single pulse output; (-D) double pulse output; (-T) multi-pulse output | |||||

maximum pulse energy | ≥1J@1064nm ≥500mJ@532nm | ≥2J@1064nm ≥1J@532nm | ||||

repetition rate range | 1-10Hz | |||||

beam pattern | TEM00/ VRM | |||||

energy stability (after warm up) | ≤2%, over 2 hours | |||||

Pulse Width | ≤9ns | |||||

Beam diameter | ≤12mm | ≤16mm | ||||

Beam divergence full angle | ≤0.5mrad | |||||

Operating conditions | ||||||

warm up time | <10 minutes from standby mode | |||||

temperature range | 20-25℃ | |||||

humidity | 20%-80% | |||||

Electrical and Chiller Equipment | ||||||

power input | 220 AC, 50 Hz | |||||

Grid configuration | Simplex | |||||

Water flow (laser head) | >6L/min | |||||

heat load | <1500W | |||||

physical properties | ||||||

laser head Dimensions L×W×H(mm3) | 700×100×120 | 700×185×105 | 800×300×120 | 1200×900×300 | 1200×100×300 | |

LSP controller

The composition of the laser shock peening control system is shown in Figure 1. The system uses a Nd:YAG solid-state laser with a wavelength of 1064nm, a pulse width of 9ns and a single pulse energy of 1-2J. The processing frequency of the laser is triggered from a single point, 0.5Hz. -10Hz, etc. The laser is equipped with a circulating water cooling system, a power control cabinet, etc., and the triggering and adjustment parameters of the laser can be manually controlled. The laser is connected to the industrial control/PLC integrated system, and the industrial computer is used to receive processing signals, control and output laser process parameters, including laser energy, laser pulse width, pulse frequency, spot size, etc. The laser is mainly used to generate short pulses (several ns) and high peak power density (>109 W/cm2), and the plasma shock wave is formed between the metal target and the confinement layer by laser induction.

Robot System

The laser shock peening control system includes two robots, one of which is a trajectory robot. In the process of laser shock strengthening, the robot actuator realizes the curved trajectory movement of the laser beam relative to the surface of the workpiece, so as to achieve the specified position on the surface of the machined part. Strengthen the treatment; the other is a water delivery robot, which can form a uniform and stable water confinement layer with a thickness of about 1mm to 4mm (adjustable) on the metal target, and confine the plasma between the confinement layer and the metal target. . The trajectory robot used is a six-axis manipulator, which realizes complex surface processing trajectory operations.

Guided and flexible optics

The light guide arm is shown in the figure below: It adopts the standard design of 7 joints, and the output end of the light guide arm is equipped with an f100 focusing mirror, which can realize the flexible transmission and focusing of the laser beam. A light guide arm that can linearly or reflectively change the direction of a laser in a long sawtooth-shaped arm that is manually operated by a human hand, comprising: joints arranged in the joint part, a series of relatively inclined mirrors, and adjustment in the handle at the exit end of the laser beam. The focus mirror is characterized in that: the mirror surface is connected with the mirror shell through adjustment bolts, and an elastic pad is sandwiched between the two. Through the adjustment of the light guide arm, the direction of the laser output can be changed in real time to realize the flexibility of the light path. The reference appearance of the light guide arm is as follows:

LSP system advantages

(1) Good applicability

1. Suitable for surface strengthening of various metal materials

LSP utilizes high power density laser to act on the surface layer of metal material, induces plastic deformation and grain refinement, and forms deep residual compressive stress. Applicable to various metal materials (Cr/Ni/Ti/Al alloy, stainless steel, etc.). Surface strengthening.

2. The influence of surface roughness is small

After LSP treatment, the micro-pits on the surface of the material are micron-scale, which is smoother than the traditional shot peening surface (special process requires mold LSP fine grinding).

3. No thermal effect on the workpiece

LSP uses the "mechanical effect" of the laser shock wave to modify the surface of the material to improve the fatigue resistance of the material. The machining process has no thermal effect on the workpiece.

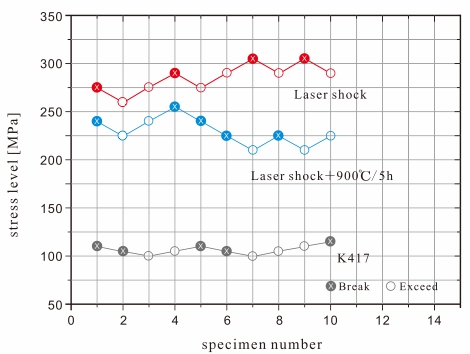

(2) The effect is better

1. The residual compressive stress layer is deep

The depth of residual compressive stress exceeds 1mm (residual stress of individual materials reaches 2mm), which is 5-10 times that of conventional surface strengthening.

2. High residual compressive stress value

Taking typical materials as an example, the maximum residual compressive stress value of titanium alloy, stainless steel and superalloy after LSP treatment exceeds 600800800 MPa respectively.

3. The microstructure of the material is more compact and stable.

LSP induces high-density dislocations and grain refinement, has good stability under certain high temperature conditions, and can significantly improve the fatigue properties of materials.

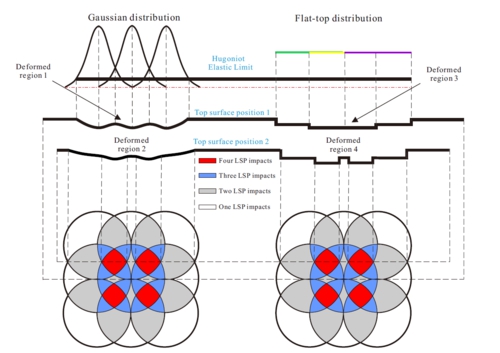

(3) Strong controllability

Through precise control of laser parameters and process parameters, LSP can process parts/parts that are difficult to handle by traditional processes.

1. Controllable laser parameters

It can precisely control parameters such as laser power density, spot, pulse width, etc.

2. The process parameters are controllable

It can precisely control parameters such as LSP enhancement path, times, lap rate, impact mode, etc.

3. Complex parts/site reinforcement

LSP strengthening treatment can be performed on ultra-thin members, small hole sides, blade teeth, blade grooves, gear parts, and the like.

We are a laser manufacturer and have been producing many different types of laser systems for over 22 years, and we have over 10 years of experience exporting our systems overseas. The technology comes from Germany, and the system comes from China. Good value for money. Please feel free to contact us for more information, thank you!