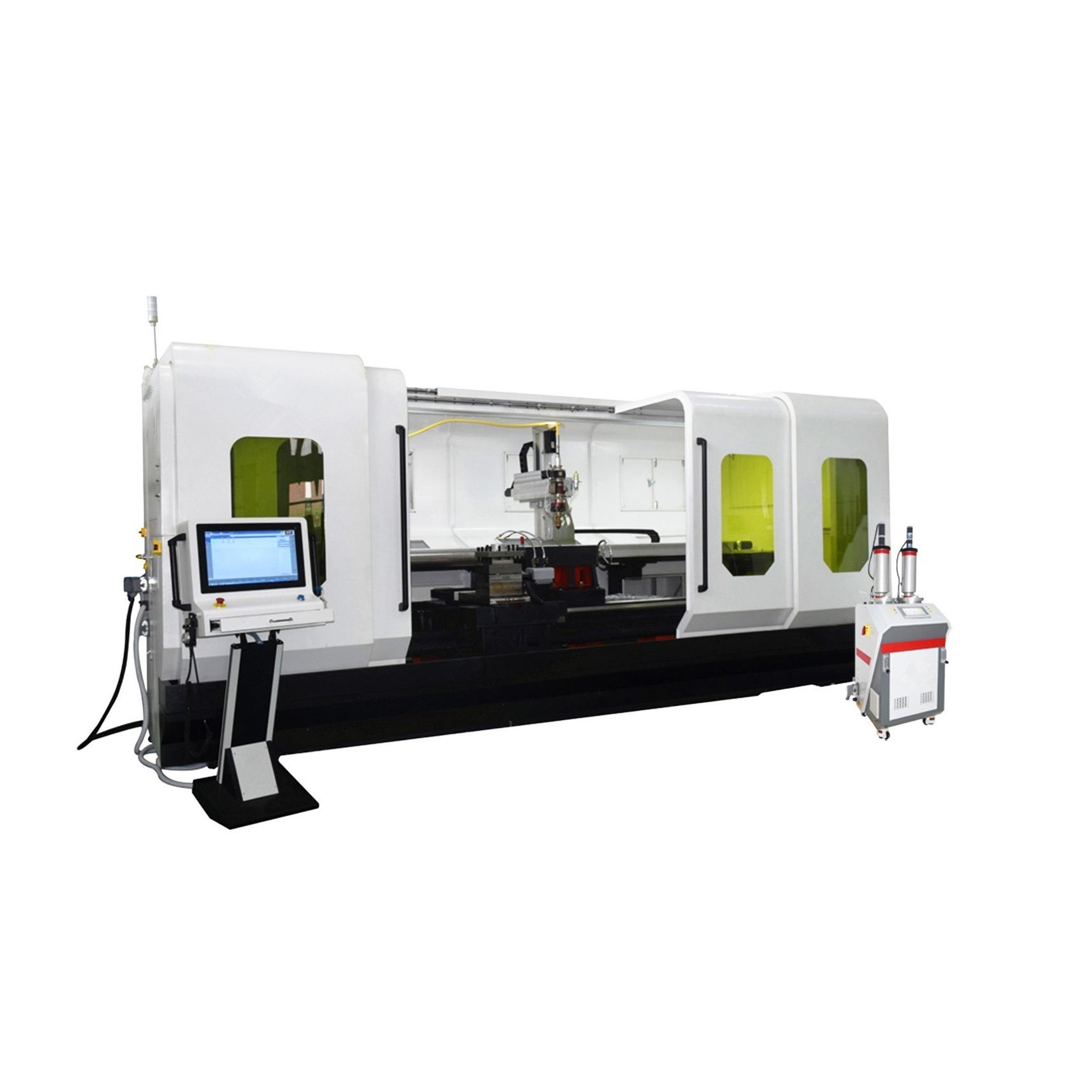

CNC Laser Dressing Machine/Robotic Laser Dressing Machine

- $9999.00 /set

- 1 set

- Sunrise Mechatronic Technology Co.,Ltd

- Jiangsu, China

- Ms Sherry Qiao

PRODUCT DETAIL

| CNC or not: | Yes | Mechanical test report: | if |

| Laser source brand: | Raycut/Max/IPG | Type of machine: | CNC Laser |

| Showroom location: | Turkey, Germany, Vietnam, India | Main selling point: | high accuracy |

| Applicable industries: | Building Materials Stores, Manufacturing Plants, Mechanical Repair Shops, Construction Engineering, Energy & Mining | payment terms: | wire transfer |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | place of origin; place of origin: | Jiangsu, China |

| Laser Type: | fiber-optic laser | Marketing Type: | Hot Products of 2021 |

| Warranty: | 1 year | Health status: | new |

| Applicable materials: | Metal | Weight (kg): | 3000kg |

| Core Components Warranty: | 1 year | Video external inspection: | if |

Product display

Product Description

content | parameter |

laser | 0.5-20kW, optical fiber, semiconductor, disc, etc. |

robot | Weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc. |

Laser processing head | 0.8-50mm round, square spot, size can be customized, coaxial, on-axis powder feeder |

Powder feeder | Airborne, gravity conveying, powder feeding accuracy ≤ soil 2%, powder feeding amount 10-150g/min, single group, double group |

chiller | Single temperature, dual temperature, and cooling capacity are selected according to the laser |

Optional accessories | Inner hole cladding head, temperature closed loop, online detection, distance detection, offline programming, molten pool monitoring, etc. |

Input voltage | 360-480V three-phase five-wire system@50 60Hz |

The main components | Laser, cooling device, powder feeding mechanism, processing table, etc. |

Laser selection | CO2 lasers, solid-state lasers, fiber lasers, semiconductor lasers |

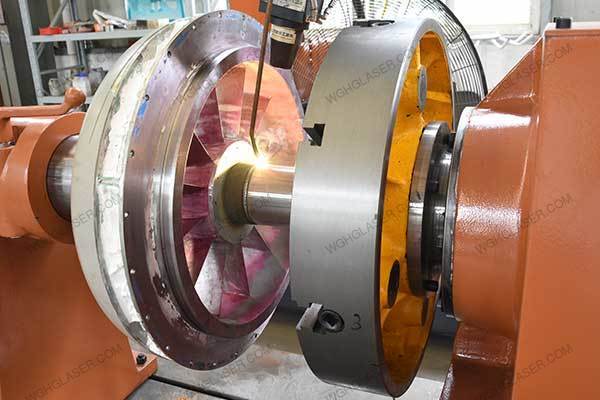

The cladding has low dilution and strong bonding. The metallurgical bonding with the matrix significantly improves the wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical properties of the surface of the matrix material, so as to achieve the purpose of surface modification or repair. Meet the specific performance requirements of the material surface and save a lot of material costs.

Including mining machinery, petrochemicals, electric power, railways, automobiles, ships, metallurgy, aviation, machine tools, power generation, printing, packaging, molds and other industries.

VIEW MORE

YOU MAY LIKE

Other Products

-

Multi-axis linkage flexible CNC high-energy laser cladding machine$20000.00 / set

Multi-axis linkage flexible CNC high-energy laser cladding machine$20000.00 / set -

Laser heat treatment cladding machine metal mold bearing steel gear rail saw blade laser quenching machine$20000.00 - $50000.00 / set

Laser heat treatment cladding machine metal mold bearing steel gear rail saw blade laser quenching machine$20000.00 - $50000.00 / set -

Wholesale CNC Laser Welding Machine 0.5kw-20kws$5000.00 - $8000.00 / set

Wholesale CNC Laser Welding Machine 0.5kw-20kws$5000.00 - $8000.00 / set -

Professional Factory Manufacturing Fiber Laser CNC Laser Cladding Machine Robot Laser Cladding Machine$9999.00 / set

Professional Factory Manufacturing Fiber Laser CNC Laser Cladding Machine Robot Laser Cladding Machine$9999.00 / set -

CNC laser quenching machine/robot laser quenching machine$9999.00 / set

CNC laser quenching machine/robot laser quenching machine$9999.00 / set