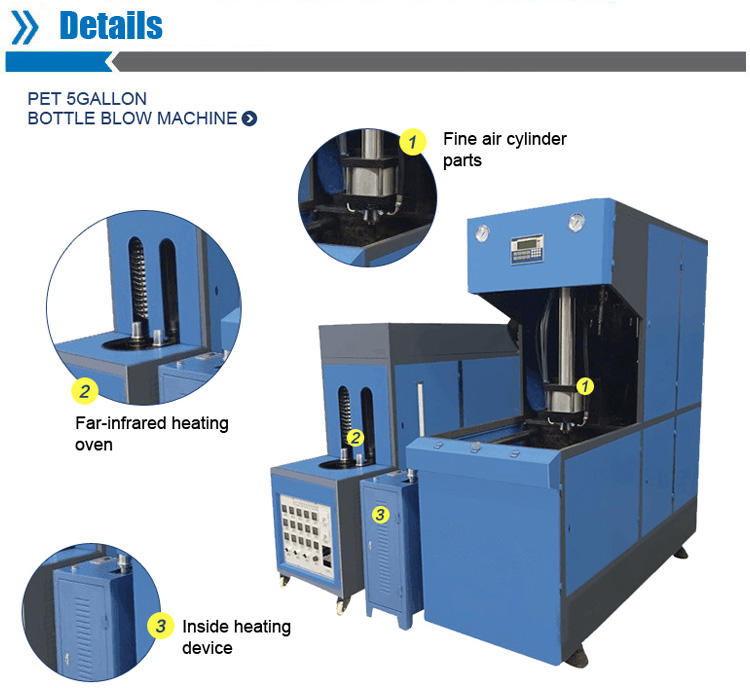

1L/2L/3L/4L/5L Double Layer HDPE Plastic Bottle Extrusion Manufacturing Blow Molding Machine

- $3500.00 / 1 - 9 sets

$3000.00 / >=10 sets - 1 set

- Cangzhou Yi Sunda Mechanical Technology Co., Ltd.

- Hubei, China

- Ms lemon Liu

PRODUCT DETAIL

| flow: | 30 l/min | automation: | semi-automatic |

| Volume of hollow part: | 200 | Local service location: | not any |

| Maximum container capacity: | 1.5 liters | automatic: | Yes |

| Insert stroke: | 100mm | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Packaging Details: | 1L/2L/3L/4L/5L Double Layer HDPE Plastic Bottle Extrusion Blow Molding Machine Wooden Pallet Packaging | carriage unit: | 60 |

| port: | Tianjin harbor | color: | customer choice |

| product name: | Plastic Bottle Extrusion Manufacturing Blow Molding Machine | Applicable industries: | Energy and Mining |

| application: | bottle | Mechanical test report: | if |

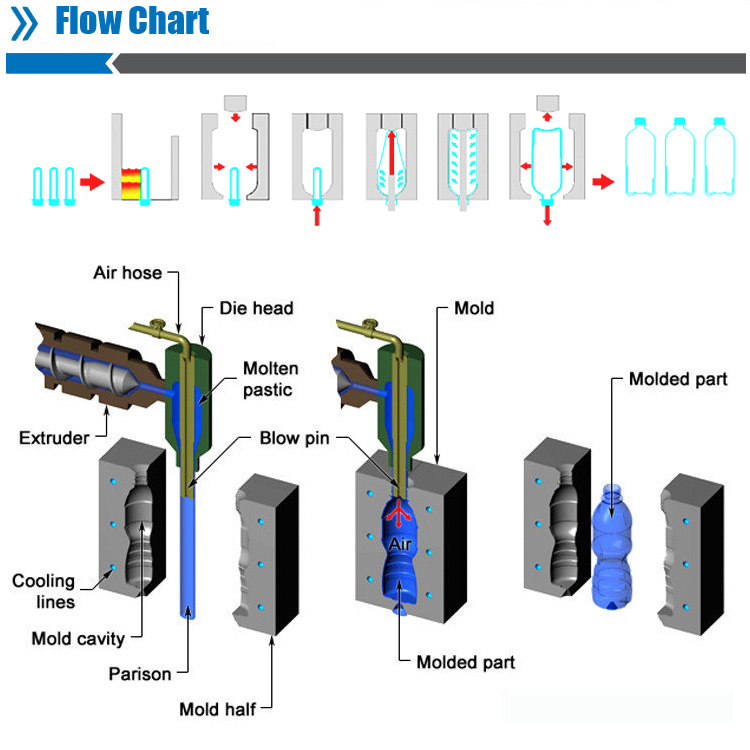

| Blow molding type: | Injection blow molding | Core components: | Gearbox, Bearing |

| place of origin; place of origin: | Hebei china | brand: | Easy Sunda |

| Main selling point: | Polychromatic | Blowing pressure: | 35 kg/cm² |

| Certification: | CE certification | Clamping force (kN): | 24000 |

| Video external inspection: | if | payment terms: | L/C,Western Union,D/P,D/A,T/T |

| Voltage: | 380V | Weight (kg): | 1600 |

| Warranty: | 3 years | Core Components Warranty: | 1 year |

| Supply capacity: | 2 sets per day and 50 sets of semi-automatic blow molding machines per month | Showroom location: | not any |

| Health status: | new | High pressure valve brand: | ATA |

| Marketing Type: | New product | Clamping force: | 24000 kg |

| Dimensions (L*W*H): | 3.33*0.6*2m | Cavity Spacing: | 120mm |

| Power (kW): | 38 | Plastic Processing: | pet |

Our machines can produce PET bottles in different shapes. It can blow bottles from 100ml to 6000ml and is widely used in production

Mineral water, carbonated drinks, juice, medicines, oil bottles, oil bottles, wide-mouth bottles, etc.

Counting function and time control precision to 0.1 second control on very beautiful panel; infrared heater ensures

It can be fully used for preforms with different wall thicknesses and maintains a uniform softening of the entire preform body. This

The cooling system ensures the neck section and heated internal temperature to maintain the perfect roundness of the bottle.

Mineral water, carbonated drinks, juice, medicines, oil bottles, oil bottles, wide-mouth bottles, etc.

Counting function and time control precision to 0.1 second control on very beautiful panel; infrared heater ensures

It can be fully used for preforms with different wall thicknesses and maintains a uniform softening of the entire preform body. This

The cooling system ensures the neck section and heated internal temperature to maintain the perfect roundness of the bottle.

VIEW MORE

YOU MAY LIKE