Blister Automatic Blowing Injection Molding Machine

- $20000.00 /set

- 1 set

- Hangzhou Dingchuan Import&export Co., Ltd.

- Zhejiang, China

- Mr Andy Chou

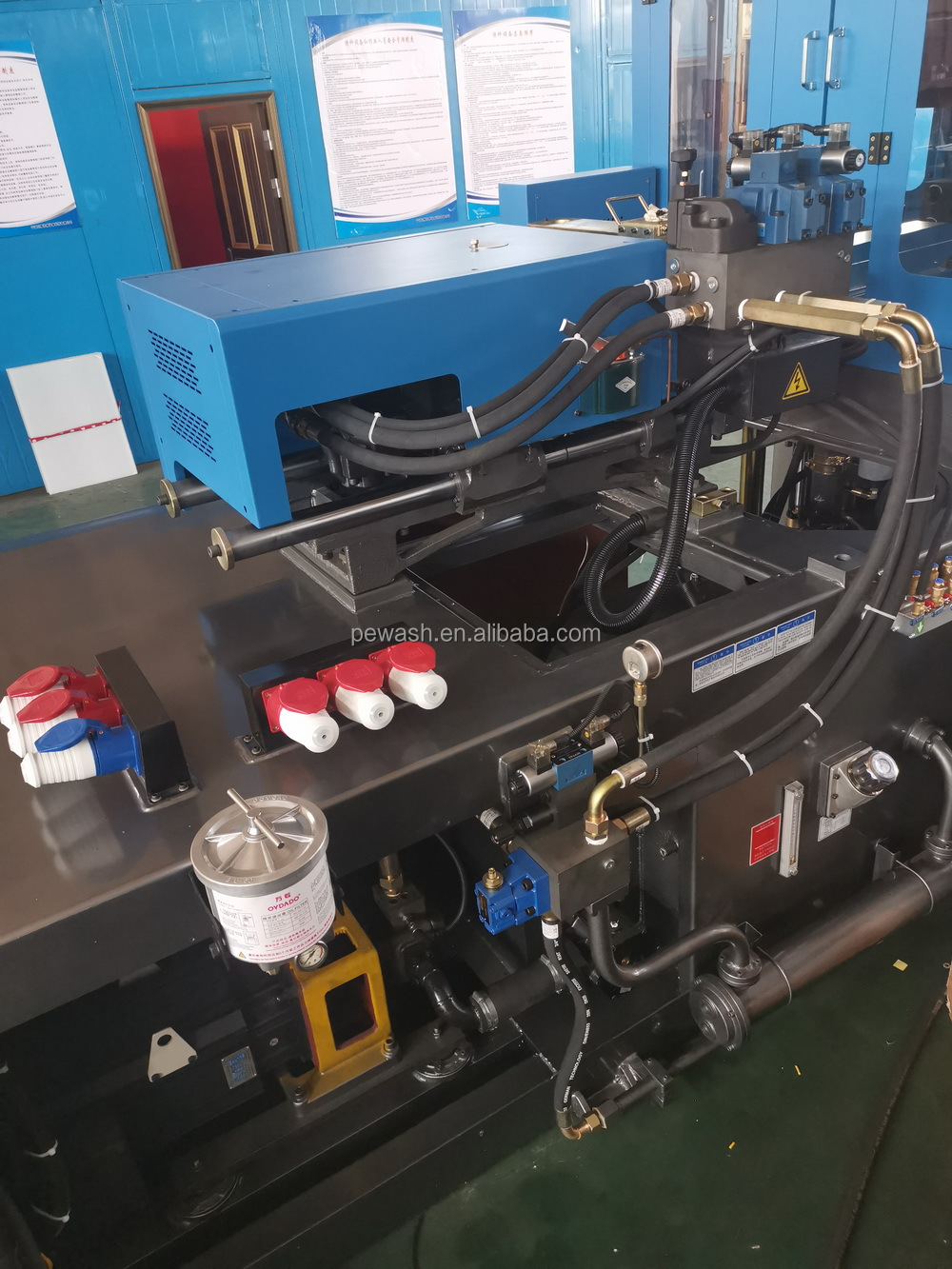

| Packaging Details: | container | Main selling points: | flexible manufacturing |

| Marketing Type: | Hot Products of 2022 | Dimensions (L*W*H): | 4900*4650*2700mm |

| Voltage: | Three-phase AC380V 50Hz or customized | automation: | automatic |

| Core components: | Bearings, engines, motors, PLCs | Plastic processing: | personal computer |

| Blow molding type: | injection blow molding | port: | Ningbo/Shanghai/Yiwu/Suzhou/Nanjing |

| Applicable industries: | manufacturing plant | Mechanical test report: | if |

| Video shipment inspection: | if | payment terms: | L/C, T/T |

| Supply capacity: | 200 sets per month | Core component warranty: | 1 year |

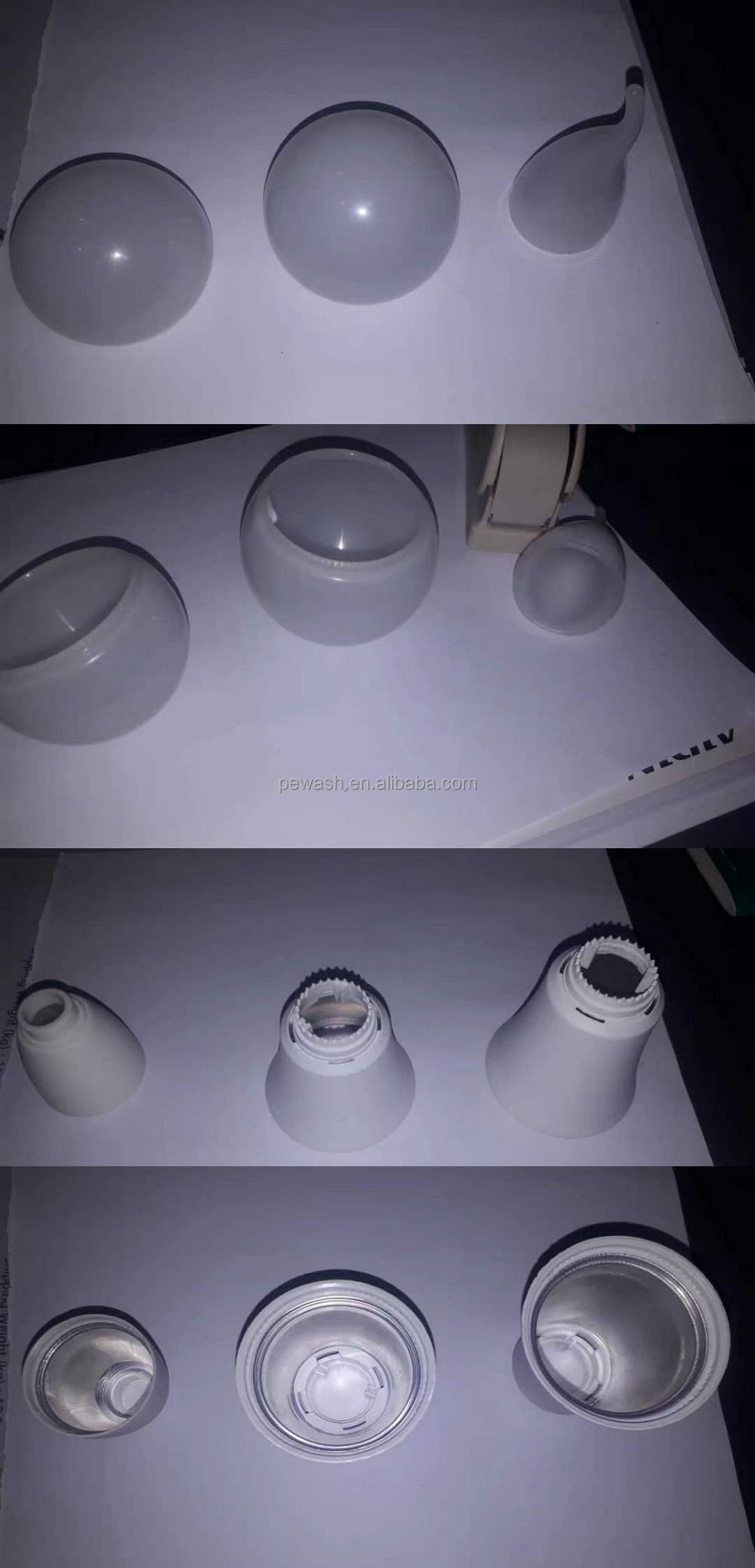

| Showroom location: | not any | application: | LED Bulb PC Cover Blow Molding |

| Power (kW): | 60 | year: | 2022 |

| Warranty: | 1 year | brand: | Sanshun |

| Weight (kg): | 6200 | Health status: | new |

| place of origin; place of origin: | Zhejiang, China | brand: | delta |

| Clamping force(kN): | 100 |

Blister Automatic Blowing Injection Molding Machine

ZC-800 LED Bulb PC Cover Injection Blow Molding Machine LED Bulb Production Line

LED Bulb Production Line Contact: wiki wong

Mobile/WeChat/whatsapp: +8613738082939

LED Bulb PC Housing Blow Molding Machine, LED Bulb Aluminum and PC House Making Machine,Plastic coated aluminum shell led light bulb, PP+ aluminum shell LED light bulb production line

LED Bulb PC Cover Injection Blow Molding Machine Model ZC-800

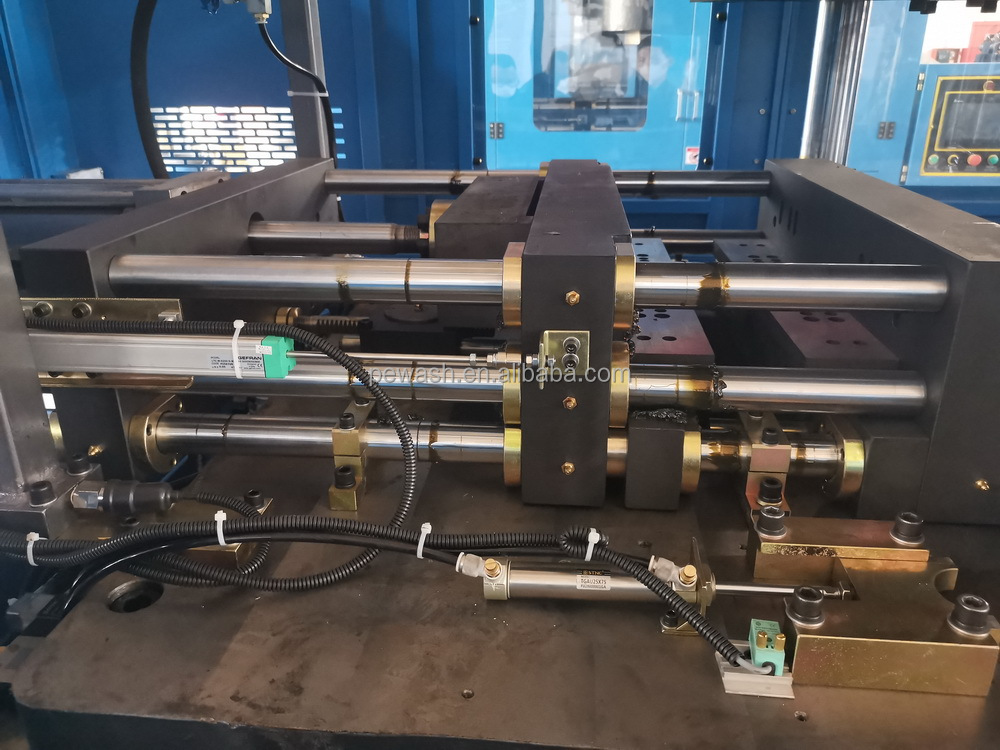

Main technical parameters of LED bulb PC cover injection blow molding machine

| Model: ZC-800 | ||

| Screw diameter | mm | 42 |

| Screw speed | Rotating speed | 0-200 |

| Theoretical injection volume | ml | 300 |

| Injection clamping force | KN | 850 |

| Applicable material | personal computer | |

| Blow clamping force | KN | 100 |

| Production speed | piece/hour |

Size 60 mm, 14 second cycle time, up to 8 per mold

Size 80 mm, 16 second cycle time, up to 6 per mold

size 100 mm, 18 sec cycle time, Up to 4 per mold

Size 140 mm, 20 sec cycle time, Up to 2 per mold

Size 150 mm, 22 sec cycle time, max 1 die |

| Gas source | MPa | 2-3 |

| Blowing power | KN | 25 |

| air jet force | KN | 10 |

| machine weight | Kilogram | 6200 |

| maximum. neck size | mm | 150 |

| maximum. body diameter | mm | 150 |

| Machine size | mm | 4900*4650*2700 |

| Parts brand | |

| computer |

Delta PLC |

| host interface |

Delta 10-inch full-color touch screen |

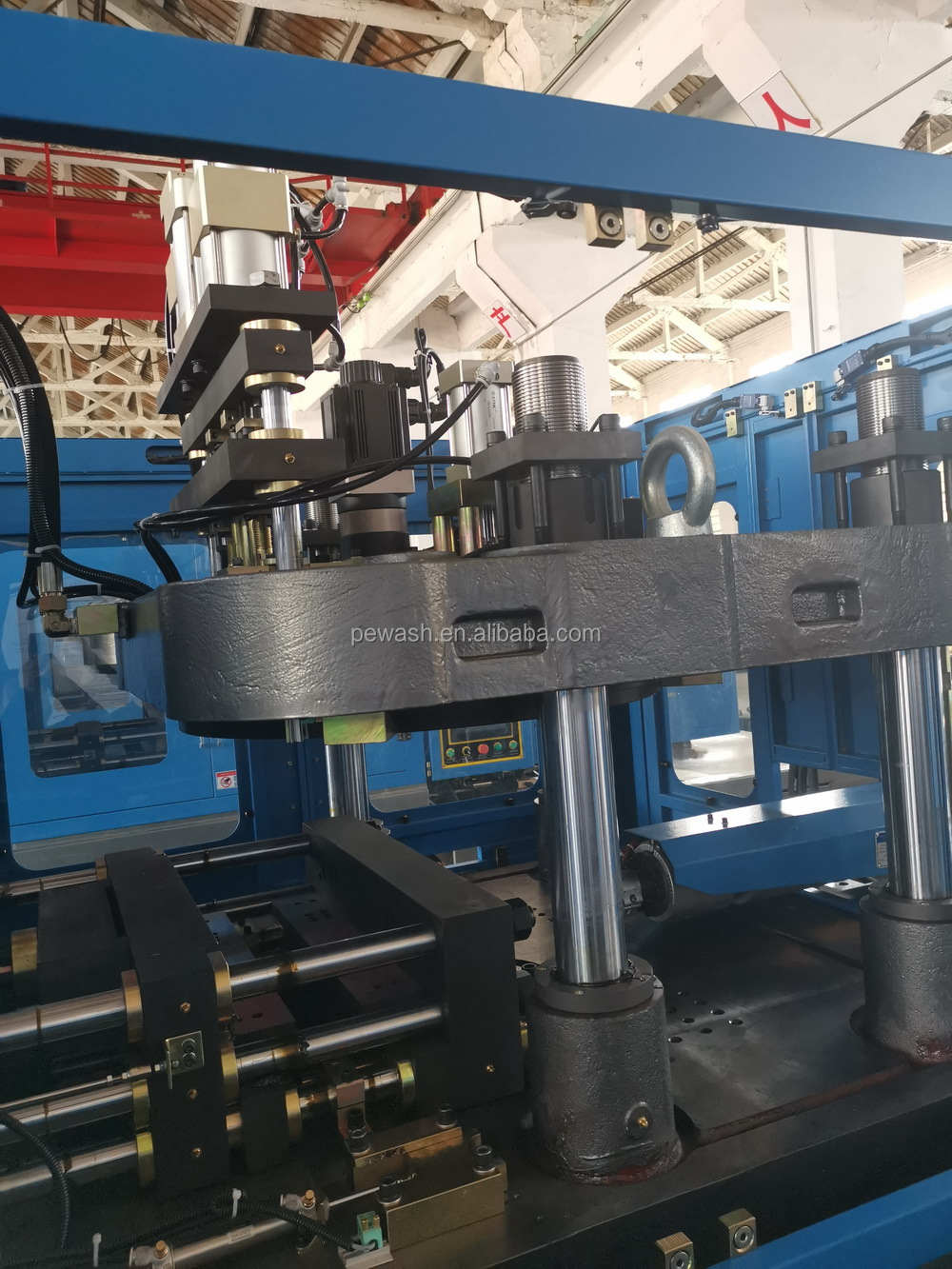

| rotatable control system |

Delta Servo Control Delta servo motor |

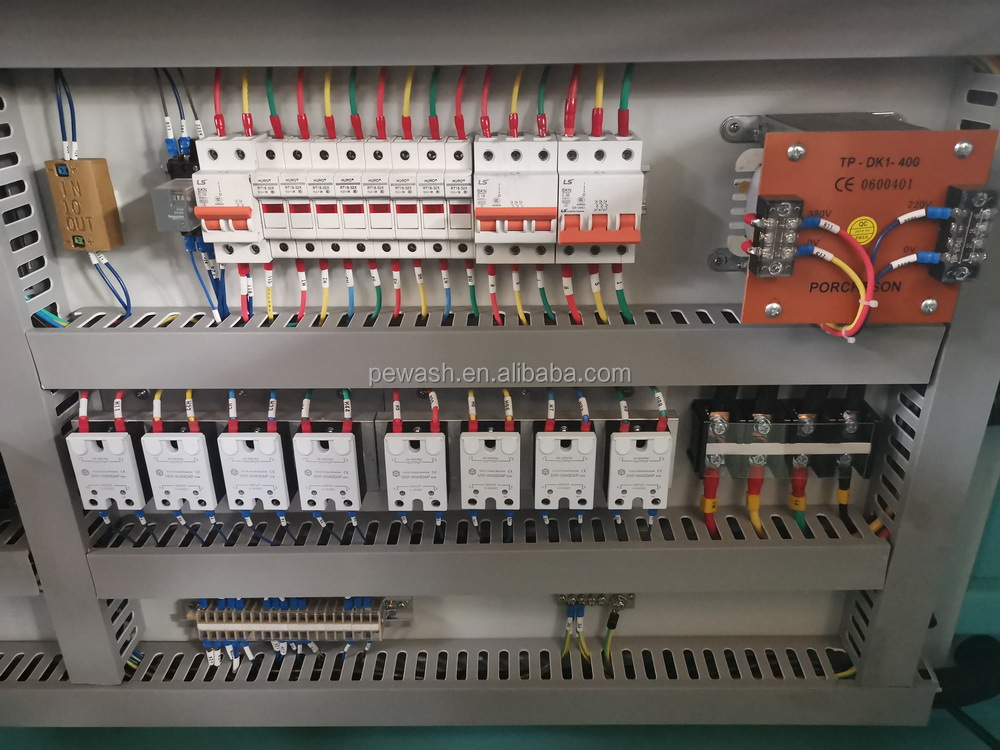

| heating control |

Delta Heating Control Non-contact solid state relay |

| Pump |

Inovance/Delta Servo Control Yunsheng servo motor High-tech vane pump |

| sealing system |

Hallate, United Kingdom |

| Hydraulic system |

High-tech hydraulic valve |

| hydraulic motor |

Denton hydraulic motor |

| limit switch |

Yingke non-contact sensor switch |

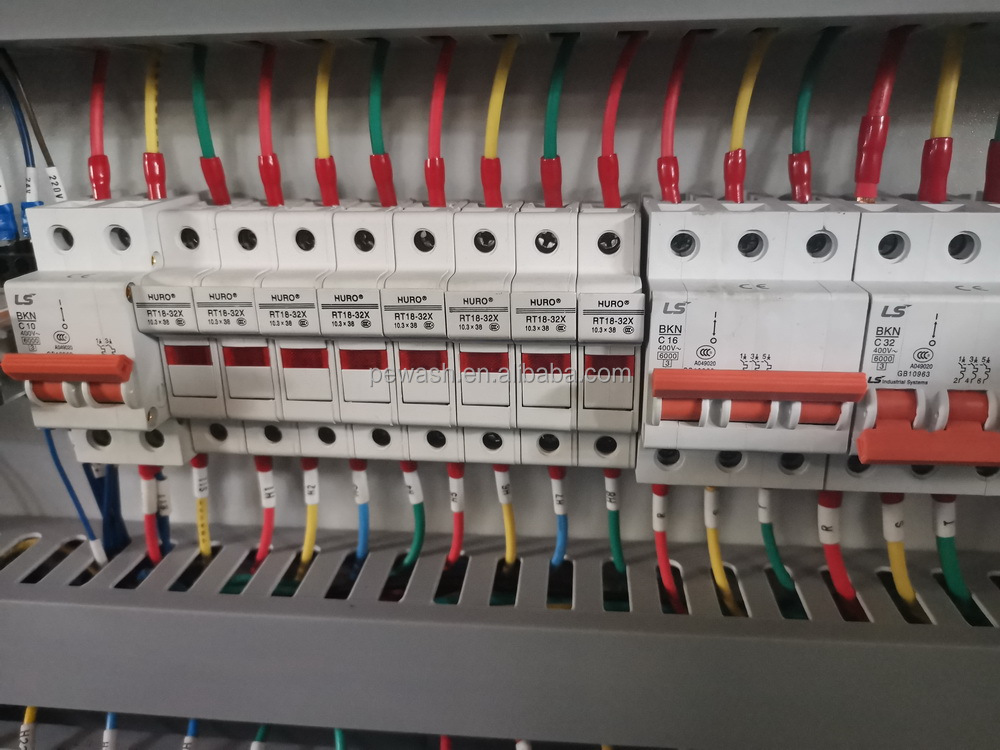

| Low voltage electrical appliances |

Yingke non-contact power amplifier Schneider contact switches and relays |

| linear scale |

Geoffrey |

The total power of the machine plus auxiliary machines and molds is 60KVA, and the power distribution of the machine increases by 40KVA. The average milliwatt is 24~27KVA, and the production efficiency is about 14S/mode (60g 7g).

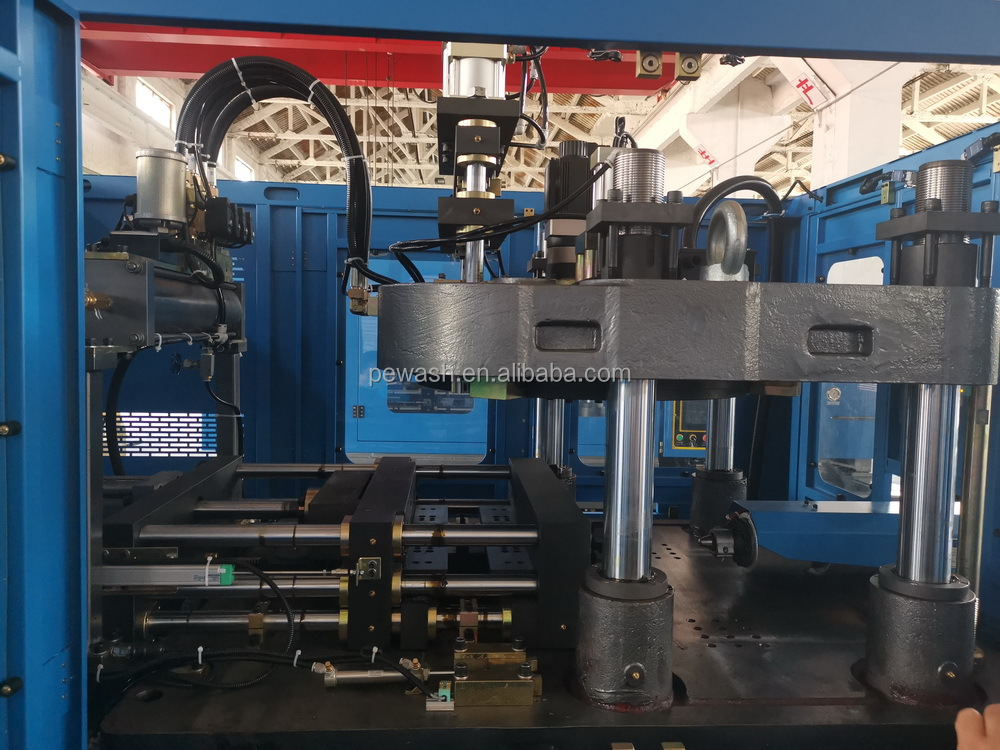

Highshine injection blowing machines generally use non-sliding molds (slider molds can also be added), and this structure of the machine will not produce flash. During normal production, there is no need for additional manual trimming, only one manual operation is required, which saves a labor compared with other brands.

Compared with the horizontal machine, the production cycle is shortened by about 4 seconds. The output of the 8-cavity mold of the Sanshun injection blowing machine is the same as that of the 12-cavity mold of the horizontal machine, and the price of the 8-cavity mold is much lower than that of the 12-cavity mold.

There are great advantages. According to each machine, add two sets of molds

One year, three to five years mold cost difference will reach the price of one machine. The mold maintenance rate and failure rate are much lower than the horizontal machine, and the price of the mold with the same output is more advantageous. It is suitable for production with a diameter of 30 to 150, while the horizontal machine is only suitable for small products. After the machine is warmed up, it can produce products normally in about 2 minutes, and it takes 15 minutes for the horizontal machine to produce products normally.

The internal parts of the mold (except the thimble) are all fixed structures, and the mold has a long service life. The machine is fully hydraulic, suitable for 24-hour start-up and long-term work, without worrying about its mechanical life.