High-efficiency injection blow molding machine for the production of plastic bottles PET automatic ring machinery IBM500/1350 CN; JIA 13000

- $6500.00 /set

- 1 set

- Zhangjiagang Huan Machinery Co., Ltd.

- Jiangsu, China

- Ms Kelly Guo

| bottle: | Chemical bottles, medical bottles, baby bottles | Applicable industries: | Manufacturing plants, food and beverage plants |

| Blow molding type: | Injection Blow Molding Machinery | Origin: | Jiangsu, China |

| brand: | ring machinery | port: | Shanghai Harbor |

| Supply capacity: | 15 injection blow molding machines per month | automation: | automatic |

| type: | Injection Blow Molding Machinery | automatic: | Yes |

| Power (watts): | 95 kW | weight: | 13T |

| Material: | Polyethylene, polypropylene, polystyrene | Dimensions (L*W*H): | 580*250*210cm |

| Packaging Details: | 1. The fuselage is first covered with a waterproof film, and then fixed on the export wooden pallet with bolts and wires. 2. Electronic control components and spare parts are packed into wooden boxes respectively. 3. Auxiliary equipment is also packed in wooden boxes. 4. All wooden materials are fumigated and certified safe for export to all over the world. | model: | IBM500/1350 |

| application: | bottle | Certification: | CE certification |

| Warranty: | 1 year | Plastic processing: | pet |

| Weight (kg): | 13000 | Health status: | new |

| payment terms: | L/C, T/T, Western Union | Main selling points: | easy to operate |

| After-sales service provided: | Engineers available to repair machinery overseas, on-site maintenance and repair services, on-site installation, commissioning and training, free spare parts, video technical support, online support | Power (kW): | 40 |

| Voltage: | 220V/260V/280V/380V/400V/440V/480V | Year: | 2019 |

High-efficiency injection-blow molding machines for the manufacture of plastic bottles

Model: IBM500/1350 injection blow molding machine

Possible products:Medicine bottle, health product bottle, cosmetic bottle, beverage bottle, etc.

maximum. Product volume:1500ml

Plastic material:PE, PP, PS, etc.

product photo

Features

This injection blow molding machine is a one-step automatic injection blow molding machine, suitable for processing thermoplastic materials such as PE, PP, PS (SAN, PMMA, PC, PETG, PEN). Widely used in the manufacture of packaging bottles for medicine, health products, food and beverage, cosmetics and other industries. This machine has one mold and multiple cavities, which can be fully automatic and continuous production. It adopts horizontal three-station dividing head, hot runner system and multi-stage injection molding system. The plastic injection, blow molding and demoulding stations work simultaneously to ensure the efficient and energy-saving operation of the machine. Our IBM series guarantees the flatness of the bottle mouth and the high precision of the inner and outer diameter of the bottle neck and the thread without any waste products. It is the standard equipment of modern environmental protection production.

Technical data

thing | IBM250/450 | IBM300/700 | IBM500/1350 |

Screw diameter | 45 mm | 55mm | 70mm |

Injection volume (maximum) | 250 cm3 | 300 cm3 | 500 cm3 |

Injection clamping force | 460KN | 700KN | 1250KN |

Blowing clamping force | 75KN | 110KN | 200KN |

total power | 40 kW | 56 kW | 95 kW |

Working power | 52-70% | 52-70% | 52-70% |

Hydraulic working pressure | 14.5Mpa | 14.5Mpa | 14.5Mpa |

compressed air pressure | 0.7-0.9Mpa | 0.7-0.9Mpa | 0.7-0.9Mpa |

cooling water pressure | 0.3-0.4Mpa | 0.3-0.4Mpa | 0.3-0.4Mpa |

Product diameter (maximum) | 100 mm | 100 mm | 100 mm |

Product length (maximum) | 200mm | 200mm | 200 mm |

Dimensions | 420*176*194 cm | 480*205*200cm | 580*250*210cm |

weight (approximately) | 5T | 8.5 tons | 13T |

sample photo

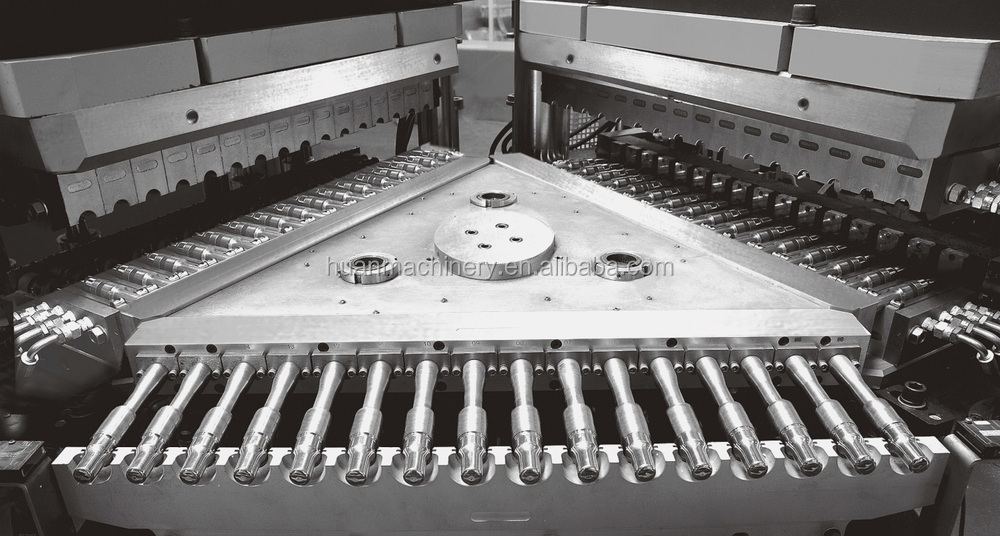

Mechanical Parts

pack

1. The fuselage is first covered with a waterproof film, and then fixed on the export wooden pallet with bolts and wires.

2. Electronic control components and spare parts are packed into wooden boxes respectively.

3. Auxiliary equipment is also packed in wooden boxes.

4. All wooden materials are fumigated and certified safe for export to all over the world.

After-sales service

1. We provide you with free machine operation training in China.

2. Provide free inspection and installation of machines in the buyer's factory, but the cost of visa, air ticket, board and lodging shall be borne by the buyer.

3. Spare parts for the machine and auxiliary machines can be provided by us.

4. The warranty period is one year under the normal operation of the machine.

contact us